Flagship Landfill Sets the Pace for LFG

By David Kaminski

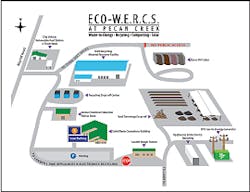

The City of Denton Landfill at ECO-W.E.R.C.S. (waste-to-energy, recycling, composting and solar) is a shining example of a modern municipal waste management facility. Over the last decade, ECO-W.E.R.C.S. has evolved from traditional solid waste landfill to a true materials management system. A single-stream MRF (operated onsite by Pratt Industries) separates plastics, metal, wood, and cardboard, while in the landfilling operations, C&D waste and concrete are removed from the wastestream before filling. The city also uses separate curbside greenwaste collection and operates a composting facility that produces and sells “Dyno Dirt,” a product made primarily from yardwaste and waste-activated biosolids from the Pecan Creek Water Reclamation Plant nearby.

The landfill’s operations have also been on the leading edge of landfilling practices and technologies. Daily cover operations utilize removable tarps during the weekdays to minimize air space used, with a sandy clay soil cover layer placed before the weekend. This method of daily cover management also serves to improve moisture distribution in the waste, which helps to increase landfill gas generation and speeds degradation of organic waste. Of course, renewable energy from landfill gas is another facet of Denton’s overall waste management strategy. In 2008, the city installed a landfill gas collection system to collect and use landfill gas as a green energy source. Covering the entire 63 acres of current waste in place, the gas collection system uses over 70 vertical gas collection wells and 30 horizontal gas collectors.

Denton’s landfill-gas-to-energy plant currently produces 1.6 MW of power, running a Cat 3520 generator that operates consistently at over 99% efficiency. The energy plant is connected to the Denton Municipal Utilities electric grid, providing power for approximately 1,600 homes in the Denton area, with the plant designed for future expansion as landfill gas production increases. All of the landfill gas collected goes to run the LFGTE plant; the flare system runs only if the engines are down for maintenance. The advanced engine control system notifies the plant operator via cell phone if the methane concentration drops below the desired preset alarm levels.

To maximize LFG generation, Denton’s landfill uses an enhanced leachate recirculation system. In 2009, the landfill received regulatory approval for the recirculation system, which utilizes both the leachate collected from the underdrain collection system and stormwater amendments to increase moisture content in the waste. The horizontal collectors serve as a “dual purpose” system to introduce the leachate and amendment water into the waste and then are switched back to vacuum to extract landfill gas. A unique method of measuring the efficiency of the system was developed in conjunction with the University of Texas at Arlington. Using resistivity imaging (RI) technology, the moisture distribution throughout the waste is profiled and color mapped in 2D. This advanced tool helps the site operators determine where to direct the liquids within the cells to improve gas generation rates and minimize operating issues from excess liquid accumulation.

As with all LFGTE systems, maintaining the high quality of the gas is a daily challenge. Keeping the methane concentration above 50% while minimizing air intrusion into the collection system is the goal. Richard Shurley, LFG technician, describes the challenge of balancing the wellfield and maintaining steady vacuum and gas flow. “The system runs at a low vacuum, between 7 to 12 inches, so a small change in the vacuum at a well can cause over-pulling and bring air into the system.” The LFG wellhead design that had been used at the site utilized common PVC plastic gate valves to control the gas and a pitot tube system to measure the gas flow rate. Over time, Richard found that the gate valves didn’t offer adequate flow control: Small adjustments in the valve setting were causing too much change in the vacuum applied to the wells, which left him with a number of wells that “require constant attention” to maintain gas quality. Richard also experienced problems getting accurate flow measurements with the pitot tube system. “The pitot tubes get buildup on them from condensate in the gas. I constantly have to clean them to remove the crust. I’ve also seen lots of fluctuation in flow readings, especially at lower flow rates.” These challenges with managing the wellfield led the Denton landfill to look for something better.

David Dugger, landfill manager for the city of Denton, met with his operations and environmental compliance team to find an alternative wellhead technology. They decided on the Precision Quick-Change Orifice Plate Wellhead, manufactured by QED Environmental Systems of Dexter, MI. The heart of this technology is QED’s Fine-Tune Control Valve, an angle-globe valve uniquely designed for LFG applications. Unlike traditional plastic gate valves, it allows an operator to easily and precisely regulate the gas flow across the entire range of valve movement and can finely tune gas flows in very small increments, even under 10 CFM. Flow measurement is achieved using an innovative “quick-change” orifice plate system. Building on proven orifice plate technology, the plates in the Precision wellhead can be easily changed by one person in less than a minute-just twist the winged collar a half-turn to change the plate, then close the collar with another half-turn. This design eliminates the need to shut down gas flow, break any pipe connections, or rebalance the well. The operator can quickly verify the orifice plate size without any disassembly by simply removing the dust cap and reading the orifice size etched on the plate tang. Being able to quickly and easily change to the most appropriate size plate for the specific flow conditions result in more accurate flow measurement readings, giving operators the ability to achieve high-quality gas production while maintaining regulatory compliance.

The benefits of the Precision wellheads were quickly realized by the Denton team. According to Shurley, “The QED wellheads have made life a lot easier. The metered scale lets me look at a well and know where I’m at without having to take a measurement, and the orifice plates can be matched to the flow of each well.

“Having the right plate size not only provides a better measurement, it also acts like a safety valve to prevent over-pulling on the well with fluctuations in system vacuum and gas flow.”

Dugger agrees. “The QED wellheads give us better control over gas flows. From an owner’s perspective, it’s nice to be able to be able to drive across the site and see the valve settings from a distance.” They’ve also seen an improvement in the consistency of gas collection with the large temperature swings they get from day to day, especially in the transition from spring to summer and fall to winter.

“Our contractor can maintain the well field with greater ease, especially changing the orifice plates as the flows change with the seasons.”

Ami Reeder, the environmental technician at the Denton site, is responsible for the operation of the enhanced leachate recirculation system. Ami can see a labor saving benefit in the Precision wellheads. “Right now, when I shut off the vacuum to the horizontal collectors to inject water and leachate, I have to mark the valve handle with a pen and count the valve turns. Adding the QED wellheads with the metered scale will make it easier to return to the previous wellhead settings.” Mike Fogle, Denton’s regulatory compliance inspector, adds, “This improves cooperation between the city and our contractor, since we don’t interfere with their wellhead settings.”

Denton sees these improvements in its landfill gas collection system operation as an example of the commitment to ongoing process improvement at the ECO-W.E.R.C.S. facility. Moving to cutting-edge LFG control technology assures higher-quality gas and more consistent energy plant operation, all while maintaining regulatory compliance. It’s a win-win decision for the Denton team.

Author’s Bio: David Kaminski is senior vice president with QED Environmental Systems at Clayton, CA.