Company provides solutions to overcome complexities of stormwater management logistics

Project logistics and staging materials for installation in stormwater management projects can often add significant unbudgeted costs to projects. This example between Plastic Solutions Inc. in Winchester, Virginia, Core & Main in San Bernardino, California, and Norstar Plumbing and Engineering in Alto Loma, California, reviews how product design was leveraged to reduce costs and meet project objectives.

When Core & Main was bidding on a storm drain improvement project in Chino, California, requiring 36 trash racks, logistics costs and pre-installation staging had to be taken into consideration. Given the project’s proximity to a heavy traffic area, a product that can withstand the elements, not rust or become discolored, was also considered. Core & Main’s outside sales representative knew the StormRax Round Series was the preferred choice, however he needed to ensure that logistics from Virginia and staging costs for 36 trash racks did not impact his customer’s budget.

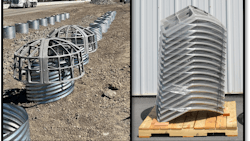

A design principle while developing the StormRax innovative line of trash racks is to be able to ship them as components for assembly in the field. The team from Plastic Solutions presented the option of shipping as components and the Core & Main and Norstar team were able to build a plan to solve the challenge. The team determined the best solution was to ship the components from Virginia to California to reduce the impact of logistics and staging costs, then assemble the StormRax as installation progressed on the job site. This solution changed the shipment from eighteen 57-inch x 57-inch pallets to ten 48-inch x 48-inch pallets, resulting in more than a 60% reduction in the footprint of the cross-country shipment and saving valuable space on a roadside jobsite.

Plastic Solutions

877.877.5727 | www.plastic-solution.com