Summary of ASCE Stormwater Manufactured Treatment Devices Certification Guidelines

With the advent of EPA’s National Pollutant Discharge Elimination System (NPDES) permits and subsequent total maximum daily load (TMDL) permits, many local, state, and industrial entities are obligated to treat stormwater runoff before discharging to receiving waters. Common treatment methods such as retention ponds, detention ponds, and wetlands can achieve economies of scale where land is available for large best management practices (BMPs). However, alternate treatment methods are utilized in urbanized areas with land and other limitations. Manufacturers have responded and developed a wide range of structural BMPs, referred to in this report as manufactured treatment devices (MTDs), either as hydrodynamic separators or filters. The need to verify and certify pollutant removal effectiveness for regulatory compliance in different regions of the country is problematic, time-consuming, and expensive for affected parties. While several certification and verification programs exist at local, state, and federal levels, there is no consistent protocol at a national level. Therefore, the American Society of Civil Engineers (ASCE) developed a Joint Task Committee on Guidelines for Certification of Stormwater BMPs. The committee was sponsored by the Sustainable Stormwater Infrastructure Committee of the Water, Wastewater, and Stormwater Council and the Wet-Weather Flow Technologies Committee of the Urban Water Resources Research Council of the Environmental and Water Resources Institute of the American Society of Civil Engineers and consisted of 63 members from academic, regulatory, consulting, practitioner, and manufacturing backgrounds.

Purpose

This guideline has two primary purposes. The first is to develop a protocol for assessing the efficiency of MTDs used for physical separation of nondissolved solids from stormwater runoff, including the assessment of scouring of settled particles under high-flow conditions. The removal of trash, leaves, and hydrocarbons are not included in this protocol. The second is to aid regulators in establishing certification programs for MTDs with a broad set of analytical tools that could be adapted for local regulatory agency needs.

The following critical components are addressed in these guidelines for MTD certification: laboratory testing, scaling relations, field testing, data analysis and performance evaluation, data reporting, inspection and maintenance, and verification and certification programs and processes. Pertinent sections of the guidelines are discussed in this article.

Existing Verification and Certification Programs

EPA regulates water quality through NPDES permits. Because of this system, several states and regional entities have proactively developed regulations to manage emerging innovative technologies aimed at reducing pollutants discharging into receiving waters. The programs evaluated and used in part as a basis in these guidelines included Environmental Technology Verification (ETV), the Technology Assessment Protocol-Ecology (TAPE) program, the Technology Acceptance Reciprocity Partnership (TARP) program overseen by the New Jersey Corporation for Advanced Technology (NJCAT), the Water Environment Federation’s Stormwater Testing and Evaluation for Products and Practices (STEPP) committee, and the International Stormwater Best Management Practices Database (BMPDB.) Other states and organizations also have programs regulating MTDs to various extents. The need for a national standard to test and verify MTDs is widely acknowledged.

Laboratory Testing

Highlights of testing procedures for hydrodynamic separators are as follows. A quality assurance project plan (QAPP) shall be developed for appropriate MTD testing. Considerable effort was expended to develop a protocol for laboratory testing where variables such as flow rate, concentration, particle size, and settling velocity distribution could be controlled to provide statistically valid predictions of MTD sediment removal efficiency performance. The first objective was to define the size of sediment particles used for testing. Most existing certification programs use the variable of total suspended solids (TSS), which is a holdover variable from the era of ultrafine solids greater than 2 microns in diameter defined for wastewater treatment plant discharges. A growing number of studies have demonstrated that particulate matter (PM) from stormwater runoff has different properties than those in wastewater with respect to pollutant distribution, PM shape, particle size distribution, and specific gravity (Rosener et al. 2007, Makepeace et al. 1995, Sansalone et al. 1998, Sansalone and Cristina 2004, Li et al. 2005). Therefore, this guideline recommends using a mass balance methodology that measures the removal efficiency of all solids entering and leaving an MTD. It is also recommended that the parameter of suspended sediments concentration (SSC) be used to more accurately measure sediment concentrations, rather than the parameter of TSS. Independent, rather than a manufacturer’s, laboratories should be utilized for MTD testing. Data collection and analysis should be undertaken by qualified personnel.

A maximum design treatment rate (MDTR) should be used to determine testing flow rates at 25%, 50%, 75%, 100%, and 125% MDTR. The MDTR is defined to be the optimum operating rate for the purposes of these guidelines. Sediment particle size ranges should be selected representing particle sizes in the region where certification is desired. A minimum of three discreet particle ranges will be used for testing (e.g., 63 to 68 μm, 149 to 210 μm, and 354 to 420 μm.)

Testing methods will also be undertaken to quantify scouring and resuspension of deposited sediment. Similar testing methods were also developed for filtration MTDs, with special attention paid to particle sizes, the rate of filtration capability loss as the filter becomes blocked, flow rates, head loss vs. surface loading rate on a constant head basis, and removal efficiency based on total mass removal for variable flow rates that simulate storm events. Recommendations are provided for preparation of the laboratory report, including masses entering and removed from MTD, percent reductions by total mass and particle size classes, and removal efficiency charts.

Scaling Relations

Scaling criteria help to develop performance specifications for different sizes of MTDs without the need to test every size individually, as well as enabling the use of small-scale models to reduce testing costs. Currently, there is no industry-wide methodology for MTD scaling. Complex flow fields inside MTDs present significant challenges for developing theoretical values and formulas across the range of steady and turbulent flow regimes using the Reynolds number (R), Weber number (W), Hazen number (Ha), Froude number (F), and Euler number (Eu). Most previous research in this field concentrated on large-scale scaling such as with lakes. One equation that has met with some acceptance in the industry is the unitless Peclet number (Pe) expressed as Pe = (D*H*VS)/Q

Where:

Pe = Peclet number

D = horizontal flow dimension (feet)

H = vertical flow dimension (feet)

Q = flow rate (cubic feet per second)

Vs = particle settling velocity

The Pe is used to develop a predictive performance curve plotting removal efficiency versus loading rate for each particle size.

Theoretical methods of scaling removal efficiency calculations were developed for this guideline, but they have not been verified with actual testing. At this point in time, no reliable scaling methods are recommended for MTD testing.

Field-Testing

Field-testing of MTDs for PM removal is desirable for verification of laboratory testing results. Field verification should undergo the following steps: watershed selection, testing, analytical protocols, data evaluation, quality assurance and control measures, and data reporting. A subsequent certification process will be designed into the field verification effort to support defensible results for an MTD across a wide range of event-based loadings. A minimum number of 15 rainfall events with a minimum time between sampling of six hours should be utilized to certify an MTD performance.

One of the goals of laboratory testing is to control the measurement variables of flow rate, particle size, flow velocity, and depth of sediment buildup within the MTD to develop the predictable performance for real-life conditions. A major challenge of field-testing is that those laboratory variables are not controlled during complex rain events, thus leading to interpretations based upon multivariate conditions. One of the variables that cannot be controlled is sediment particle sizing. Pollutant matter that enters an MTD in the field includes organic material; gross solids of litter, debris, and vegetation; and sediment sizes greater than 75 microns that may or may not be suspended solids depending on flow rate and velocity within incoming pipes. While gross solids are not pollutants of concern under this guideline, the buildup of those materials inside of an MTD affects the predicted performance and cleaning intervals required for an MTD to remain effective.

A goal of field-testing is to reasonably control the variables with prudent site selection to achieve higher confidence levels of measured parameters. Some of the factors to consider in site selection are as follows:

- Select a site that normally has at least eight rainfall events per year in order to obtain 15 events over a two-year period.

- Choose an MTD that has one inflow and one outflow pipe. Additional pipes will increase costs due to increasing the number of deployed automated sampling devices and lead to increased malfunctions.

- There should be no bypass device for the MTD.

- There should be no submersion from downstream water bodies.

- Do not choose an MTD in a roadway. This leads to equipment damage and safety concerns when technicians need to park vehicles next to the MTD to collect data. Solar panels cannot be used when the MTD is in a roadway.

- Rain gauges and solar panels should not be under tree coverage or they will not function correctly.

- The MTD must be large enough to enable technicians to enter safely and take samples.

- Roadways in the watershed should have curbs and gutters. Roadside swales can filter many of the sediments, resulting in low pollutant loadings to an MTD.

After a site is selected, a QAPP should be prepared for review and approval by the certifying entity. The QAPP includes all site location data, sampling protocols, watershed data, and MTD information. Proper installation of equipment and setting flow depth mechanisms to trigger sampling is a reiterative process that typically takes several storm events to calibrate flow-weighted data gathering. Note that the MTD should be cleaned after each measured event.

Sampling and Analysis

Analysis of existing means and methods of field-testing of MTDs provided the following recommendations:

- Even though automated samplers do not effectively capture granulometric, hydrodynamic, arrival, or temporal characteristics of urban runoff (Furumai et al. 2002, Li et al. 2005), these devices are still in widespread use, reflecting a wastewater-type sampling paradigm, and should be utilized along with a rain- fall gauge at the MTD site. Manual sampling may also be used with appropriately trained personnel.

- The recommended sediment concentration methodology is SSC, though TSS may be used as a regional preference.

- The minimum rainfall event to be monitored is 0.1 inch.

- Replicate samples must be taken for manual or automatic sampling.

- Real-time radar imagery at three- to five-minute intervals is available throughout the US and may be utilized with adaptive sampling decision making to adjust sampling frequencies (one to five minutes) to capture first-flush data for SSC or TSS.

- The number of monitored storm events should be a minimum of 15 in order to achieve reasonable statistical probability, with a combination of light, average, and heavy rainfalls based on rainfall patterns in different seasons.

- The recommended minimum number of samples taken per event be calculated based upon the following formula (Rosener et al. 2007): n = 4σ2 / E2

Where:

n = number of samples to be taken

σ = standard deviation of the data

E = allowable error - Though most MTDs are evaluated by TSS removal, a large fraction of solids retained in an MTD is not reflected in mass load calculations for TSS. Therefore, a PM analysis should be taken to characterize the entire spectrum of PM. PM is composed of three fractions: suspended fraction of PM 1 to 25 microns, the settleable fraction of PM 25 to 75 microns, and the sediment fraction > 75 microns.

- A minimum of six flow-weighted aliquots must be taken, though the ideal number of aliquots is 24.

- At least one event should take place during the wet season.

- Two times during the life of the project, materials trapped on any screens (trash and herbaceous material) should be removed and subsampled for laboratory analysis using the percent organic matter test (ASTM D2974).

- Because most filtration devices are placed in offline configurations, water that bypasses a filter device should be tested with the hydrodynamic protocols designated above.

Field Data Analysis and Performance Evaluation

An MTD verification program has the primary goal of collecting and analyzing scientifically defensible data to fulfill the program’s objectives. Several data analysis approaches using statistical methods are discussed in this guideline, including each of the method’s strengths and limitations. Field studies often produce data sets that are small and not normally distributed. These types of datasets should be transformed to a normal distribution or subjected to nonparametric methods such as log transformation or applying the Shapiro-Wilk W test.

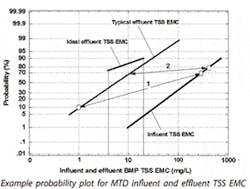

Historically, there have been many methods used to evaluate MTD field performance. This guideline discusses nine statistical approaches to MTD testing that could be utilized for MTD performance evaluation by the existing ETV, TARP, TAPE, EPA, and USEPA/ASCE BMP certification programs across the US. There is no one program or methodology better than the others. Each was developed based upon regional water-quality goals and characteristics such as soil type, weather conditions, and rainfall characteristics. Eight methods are variations of calculating a pollutant removal efficiency of loads or concentrations, and one, the Effluent Probability Method, develops relationships between influent and effluent event mean concentrations (EMCs), which is useful when local regulations require discharges to meet an effluent concentration goal (Figure 1). This method gives better removal efficiency predictions with high influent concentrations. When influent PM concentrations are low in the field, effluent concentrations are also low, indicating the MTD provides minimal removal efficiencies. Laboratory testing does not have this limitation because high influent concentrations and loads are introduced to the MTD.

MTD influent and effluent TSS EMC

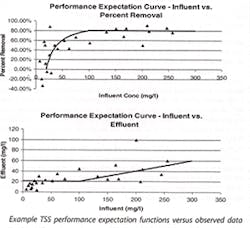

Another MTD performance calculation method discussed is SCM Performance Expectation Functions (PEF). This methodology combines effluent performance standards and an evaluation of MTD performance based on field data (Figure 2).

Data Reporting

Laboratory and field testing generate large amounts of data to include in detailed reporting. Currently, there are no reporting standards among the many state, regional, and federal agencies. With no standards, vendors struggle with discovering the data and formatting required for each of a multitude of agencies. A review of leading testing programs, including the BMPDB, was performed and used as a basis for the development of a proposed system performance evaluation report (SPER) that should become a reporting standard for MTD evaluation in the US. The SPER presents sufficient information and a framework to determine if an MTD meets performance standards within a reasonable level of statistical confidence. A consistent reporting format would enable regulatory agencies to easily, consistently, and accurately review a proposed MTD testing report within a reasonable timeframe.

The proposed SPER in this guideline started with the verification report for the New Jersey Department of Environmental Protection located at www.state.nj.us/dep/dsr/bscit/NJCAT_Fnl_Ver(Stormfilter).pdf. Next the framework was broadened to meet the data reporting criteria of the BMPDB. Reporting elements for the proposed SPER are as follows: 1) executive summary; 2) definitions; 3) site conditions; 4) technology descriptions; 5) test methods and procedures; 6) testing and sampling event characteristics; 7) MTD performance results and discussion; 8) conclusions, performance claims, and limitations; 9) third-party review; and 10) appendices.

expectation functions vs. observed data

Conclusions and Recommendations

Federal, state, and local agencies are realizing that approval, control, and regulatory oversight of MDTs is difficult without a standardized verification and approval program. Agencies rarely have the time or expertise to develop such a program. Vendors expend enormous energy, time, and funds to meet repetitive testing requirements across many jurisdictions. Several existing verification programs across the country were examined and served as a basis for the development of these guidelines. Communities could use these guidelines as a tool to develop evaluation and certification programs for sediment removal of MTDs on a localized or regional basis. The guideline is available at www.asce.org/templates/publications-book-detail.aspx?id=25461. Major recommendations from this study include:

- Laboratory Testing

a. Hydrodynamic Devices

Use of a total mass balance to calculate removal efficiencies. Use of SSC parameters rather than TSS. Test flow rates at 25, 50, 75, 100, and 125% of an MTD’s maximum design treatment rate. At each flow rate three ranges of particle sizes shall be tested. Influent sediment concentration should be 200 ± 40 mg/L of SSC.

b. Filtration Devices

Use of a total mass balance to calculate removal rate per square area and mass removal efficiencies. Use of SSC parameter and PSD. Test flow rates at 25, 50, 75, 100, and 125% of an MTD’s maximum design MDTR. At each flow rate three ranges of particle sizes shall be tested. Measurement of particle gradation at various surface loading rates. Measure head losses through a filter medium. Use an influent concentration between 100 and 200 mg/L of SSC. - Scaling rates could not be verified. Only full-scale testing of MTDs should be used.

- Field Testing. Investigation of many field-testing events showed that the many variables encountered in the field could not be accurately controlled to verify laboratory testing. There is no recommendation for the use of field testing to verify lab testing.

- Field Data Reporting. Data should be reported in a format compliant with the International Stormwater BMP Database requirements.

- Field Data Analysis and Performance Evaluation. Several statistical analytical methods were reviewed and could be utilized according to local needs. The Shapiro-Wilk test appears to accurately determine the statistical validity of a dataset. After analyzing data, they should be evaluated and compared with a performance standard. Various methods are available for such evaluation. A recommended method is a PEF that utilizes a concentration prediction for low influent concentrations that approach an irreducible concentration level, along with concentration removal efficiencies for high sediment concentrations.

- Inspection and Maintenance. Recommendations are made for inspection and maintenance intervals to ensure long-term the effectiveness of a device. Design factors are recommended to facilitate proper maintenance of an MTD. Essentials of personnel training, maintenance procedures, and record keeping are discussed.

- Verification and Certification Programs. Existing and emerging verification and certification programs were reviewed. It is critical that consistent, scientific, defendable methods are used to evaluate and verify MTD performances for sediment recommendation. Due to the many variables of performance goals and regional field conditions, there is no one best program. Each community should evaluate MTD performance goals based upon local TMDL objectives. Proper implementation of procedures recommended in the guideline can enable reciprocity of verification and performance findings between community, regional, and national programs.

References

Furumai, H., H. Balmer, and M. Boller. 2002. “Dynamic Behavior of Suspended Pollutants and Particle Size Distribution in Highway Runoff.” Water Science and Technology 46(11-12): 413–418.

Li, Y.X., S.L. Lau, M. Kayhanian, and M.K. Stenstrom. 2005. “Particle Size Distribution in Highway Runoff.” Journal of Environmental Engineering 131(9): 1267–1276.

Makepeace, D.K., D.W. Smith, and S.J. Stanley. 1995. “Urban Stormwater Quality – Summary of Contaminant Data.” Critical Reviews in Environmental Science and Technology 25(2): 93–139.

Rosener, L.A., A. Pruden, and E.M. Kidner. 2007. “Improved Protocol for Classification and Analysis of Stormwater-Borne Solids.” Water and Environment Research Foundation, Alexandria, VA.

Sansalone, J.J., and C.M. Cristina. 2004. “Prediction of Gradation-Based Heavy Metal Mass Using Granulometric Indices of Snowmelt Particles.” Journal of Environmental Engineering 130(12): 1488–1497.

Sansalone, J.J., J.M. Koran, J.A. Smithson, and S.G. Buchberger. 1998. “Physical Characteristics of Urban Roadway Solids Transported During Rain Events.” Journal of Environmental Engineering 124(5): 427–440.