In 2007, Westlake had a condition assessment performed of its primary sanitary interceptor sewer – a 6,400m pipe comprising part reinforced concrete and part poured-in-place concrete. The condition assessment was performed after a sanitary interceptor failure at a neighboring community in 2006, during which many basements were flooded with raw sewage.

Sewer projects are funded through bills collected at a flat rate of US $30.25 per quarter for residential dwellings, while that for commercial and industrial properties is usage-based. With diameters varying between 915-1,525mm, the sanitary interceptor has an average dry weather flow of 22.7ML/d and covers a sewer tributary area of 227km, which is owned and maintained by Westlake.

The condition assessment was performed after a sanitary interceptor failure at a neighboring community in 2006, during which many basements were flooded with raw sewage. Only 18 years old, this interceptor was a reinforced-concrete pipe, similar to the one in Westlake. As a result of the calamity, which also involved a fatality, residents filed multiple lawsuits exceeding US$560,000, the majority of which have now been settled.

As no comprehensive assessment of the Westlake interceptor had been undertaken since its construction, the municipality hired URS Corp of Cleveland, Ohio, to perform an appraisal.

Condition Assessment

URS performed the CCTV inspection of the entire interceptor with ADS Environmental Services of Earth City, Missouri. This was accomplished with a crawler camera and a camera mounted on a pontoon boat for downstream locations with heavy flows. In addition, all 64 sanitary manholes along the interceptor were inspected.

The CCTV inspection was analyzed by URS, and the condition assessment generated and organized in the following order:

Operation and maintenance Issues (O&M)

- Leaking joints contributing to infiltration

- Capacity-reducing obstructions

- In-pipe debris

Structural defects

- Cracks and fractures

- Microbiologically-induced corrosion (MIC)

- Open joints

Manhole inspection

- Infiltration/inflow (i/i)

- Structural defects

Assessments to prioritize defects relative to the pipe runs between manholes were carried out. This classified each run of pipe with respect to operational and maintenance issues, and structural defects. The locations of all defects were displayed in a GIS environment. Each pipe length, from manhole to manhole, was ranked for operation and maintenance, and structural condition. The system-ranking methodology allows for the values of each segment to be prioritized relative to the entire system’s defects.

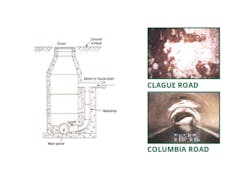

From the condition assessment in 2008, the greatest area of concern was microbiologically induced corrosion from hydrogen sulphide, which was prevalent throughout the entire system and concentrated at critical locations. These were at the connection points of the various trunk lines (458-610mm diameter) discharging into the sanitary interceptor.

At those connection points, drop manholes were located with at least a 3m vertical difference between the inverts of both pipe. Also, the downstream section of the interceptor had a large concentration of corrosion due to the proximity of the wastewater-treatment plant.

Microbiologically Induced

Vertical-drop manholes of trunk lines cause severe turbulence in the interceptor, releasing large amounts of hydrogen sulphide gas, produced from anaerobic bacteria in the sewage. Over time, the effects of carbon dioxide and hydrogen sulphide lower the concrete pipe’s surface pH to below seven, thereby providing an ideal environment for Thiobacillus bacterial growth to thrive above the flow in the crown of the pipe.

New concrete pipe has a pH of 11; pH swabs were performed at various manholes during the manhole inspection. The majority of these pH levels were below seven, so the environment was ideal for bacteria. Since the capacity of the interceptor exceeds the average dry weather flow, a large amount of the interior surface of the pipe is left exposed above the flow line.

In the presence of oxygen, hydrogen sulphide gas reacts with the Thiobacillus bacteria in this region of the pipe, converting it into sulphuric acid through an aerobic-biological process. Sulphuric acid then attacks the concrete pipe, which can lead to structural failure. At the majority of locations, corrosion form sulphuric acid was confined to within 7.5-15m either side of the manhole, with the remainder of the interceptor in good condition.

This concentration resulted from trunk lines with drop connections. The downstream section of the interceptor entering the treatment plant also had corrosion from sulphuric acid due to the changes in slope, the sewer’s horizontal alignment and the wastewater-treatment plan itself.

Design

Westlake’s design philosophy was to permanently repair the deteriorated sections of pipe to prevent further corrosion at those locations. Controlling the hydrogen sulphide gas with temporary measures was therefore not an option. Also, as most of the interceptor is located in undeveloped areas, odor control was not an issue. Due to budgetary constraints, rehabilitating the entire pipe from manhole was not an option since some sections were as long 167m. A more target-based rehabilitation method was required. As a possible solution, cured-in-place pipe (CIPP) was reviewed first. However, since the entire sewer run was not being repaired, partial liners for the deteriorated sections of that size diameter pipe were not feasible. The city then decided to perform the rehabilitation using centrifugally-cast concrete pipe (CCCP). A spray-applied cementitious coating with an anti-microbial agent called ConShield, made by AP/M Permaform.

Anti-microbial agents hinder the Thiobacillus bacterial growth on the interior surface of the pipe. This prevents the aerobic-biological process of hydrogen sulphide gas converting to sulphuric acid. The high compressive strength of the cementitious coating also improves the ring compression of the pipe. Westlake then formulated a rehabilitation project for the sanitary interceptor, associated manholes and the downstream sections of trunk lines.

The project consisted of the following:

- Interceptor cleaning

- Mineral deposit removal

- Interceptor rehabilitation by the means of CCCP

- Trunk line cleaning

- Trunk line rehabilitation by the means of CCCP

- Trunk line rehabilitation by the means of CIPP

- Manhole rehabilitation by cementitious coating

- Manhole grade ring area modifications; and

- Rehabilitation

The project was awarded in 2009 to United Survey of Cleveland, Ohio, with Kevan Taylor of Spincrete as sub-contractor. Westlake funded the entire project through to completion in 2010, without federal or state assistance. Throughout the design stage, the tight budget was a key issue; only the corroded sections of pipe were rehabilitated. The sections of interceptor scheduled for rehabilitation were cleaned by sub-contractor Brenford Environmental Services using a Sewer Hog jetter, capable of cleaning the line form manhole to manhole without bypass due to its 140kg/cm2 applied force and 1,325L nozzles. Since domestic water was unavailable in some of the isolated cleaning locations, the jetter used sewage water pumped from the interceptor; an operation that also removed the silt and debris that had accumulated at manholes following the step-cleaning process. The silt and debris were pumped through a high-speed decanting, separation and dewatering container that receives the slurry from the pump. Solids are captured while returning 99% debris-free grey water to the interceptor. The interceptor rehabilitation was performed under full bypass conditions to provide a dry pipe for the work.

Since the rehabilitation was undertaken at multiple locations, various bypass set-ups had to be established. Bypass pumping was based on wet weather flow, with the far downstream section of the interceptor having a pumping capacity of 45.4ML/d, and decreasing as work progressed upstream. Since the majority of the work occurred in winter and early spring, precipitation levels were monitored closely as the city’s sanitary interceptor experiences surcharging from infiltration/inflow. As the flow in the interceptor could increase five-fold during a major rain event, whenever the interceptor was under bypass there were pump watchmen on site to monitor the flow levels in the manholes.

Once a bypass was established, the sewer pipe was prepared for rehabilitation. Man entry was undertaken with compressed air and high pressure water to clean the pipe of any organic matter and/or deteriorated pipe fragments. Compressed air was also used to dry the pipe surface prior to the cementitious coating operation. The surface of the pipe was then washed with a concentration of anti-microbial agent to kill any active Thiobacillus bacterial growth. After the pipe had been prepared for rehabilitation, a pre-CCTV inspection was also performed to verify that the substrate could accept the cementitious coating.

This factory blended mix, made by AP/M Permaform, comprises a high-strength, high-build, abrasion-resistant mortar that develops a hardened liner, which is dense and highly impermeable. The mix was batched in a portable plant. As ConShield anti-microbial agent was batched within the mix as an admixture with water, it became an integrated component that bonded molecularly to the cement particles. The antimicrobial agent cannot wash off, delaminate or lose its effectiveness due to wear.

The CCCP coating was applied as a 12mm-thick layer on the surface of the prepared pipe by a spin-caster; this was pulled through at a uniform rate using compressed air to apply the pumped, cementitious coating around the circumference of the pipe.

Editor's Note: Scranton Gillette Communications and the SGC Water Group are not liable for the accuracy, efficacy and validity of the claims made in this piece. The views expressed in this content do not reflect the position of the editorial teams of Water & Wastes Digest, Water Quality Products and Storm Water Solutions.