The Long Haul

Following a U.S. Environmental Protection Agency (EPA) Administrative Order to reduce sewer spills and beach closures, the City of San Diego’s Public Utilities Department adopted a short-term cleaning and long-term maintenance program to access, clean and repair miles of 75-year-old sewer infrastructure located in canyons and other environmentally sensitive areas upon which the city is built.

Some program objectives include:

• completing inspection and cleaning of the city’s sewer infrastructure, located in canyons and other environmentally sensitive lands; and

• identification and implementation of efficient, effective and environmentally sensitive means to accomplish canyon sewer cleaning.

Solution

Under this “programmatic” approach, Innerline Eng. of Corona, Calif., was chosen to inspect clay sewer trunk lines, most of which run through the canyons. Most of these lines have 24-, 42- and 72-in. diameters. Access points are between 500 and 1,000 ft apart, all in environmentally sensitive areas.

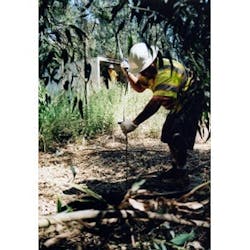

Under the watchful eye of environmental monitors whose sole job is to protect the canyons, Innerline takes great care.

“The smaller the physical footprint of whatever activity we undertake there, the better,” said Innerline President Jim Aanderud.

They must float the inspection cameras on top of active sewer flows at night, when flows are lowest.

“We’ve had a lot of challenges with overgrown vegetation at many manhole access points and an abundance of poison oak in the canyons, so being able to float our camera down a significant distance while bypassing a lot of these problem access areas would be great,” Aanderud recalls thinking early on. “We hoped a longer cable would allow us to avoid having to set up in some of these more environmentally sensitive and challenging areas, so we approached R.S. Technical Services (RST) about the possibilities of using a 5,000-ft cable with our RST TranSTAR cameras and various tractors that would give us longer runs per setup.”

RST’s engineering department set to work, and after approximately 5 to 6 months of development and rigorous testing by RST Regional Manager Bob Grenier and other team members, Innerline had a custom cable to deploy for these long runs, along with a specially designed cable drum to accommodate the longer length that was swapped into its existing cable reel.

Due to the extended length, the cable was not armored like their other RST cable, so some precautions needed to be taken during deployment.

“Armor would have been too heavy at those lengths for a tractor to pull, so we had to find places where we could set up without punishing the cable too much,” said Aanderud.

To facilitate the inspections, Innerline’s crews utilized a TrakSTAR inspection camera on a TranSTAR tractor with a special power supply that sent more voltage to the tractor, giving it more pulling torque. No special modifications were required to the camera—it has produced excellent images even at those extreme lengths. To date, they have completed approximately 300,000 linear ft of trunk line inspection.

Innerline is also inspecting San Diego’s concrete force mains. Grading differences require pressurization to allow these lines to traverse significant distances of uneven terrain. They typically only have access points every 5,000 to 15,000 ft. Crews inspect it coming from each end, meeting somewhere in the middle. Usually, the force mains are not flowing during inspection, so floatation is not required. For this application, crews use a RST Storm Drain Tractor, again using the extra torque of a special power supply to pull the longer cable farther. With their usual armored cable, they would have been lucky to get to 1,500 to 1,800 ft before it would be too heavy. With the jacketed cable, the crews can accomplish 4,000 to 5,000 ft per setup.

Result

The special cable allowed Innerline to inspect lines it otherwise would not otherwise have been able to inspect—on time and on budget. Aanderud allows that the design had a few limitations, but it got the job done.

“Dry force mains, storm drains, minimal-flow waste lines and large-diameter water lines would be great applications for this cable, because it would take a larger tractor to drag the longer cable,” he said. “We haven’t used it sufficiently yet to prove its capabilities on our day-in, day-out applications for durability like our RST amored cable, so we prefer to keep it for special projects where we have long runs with few access points and need to get in and out quickly.”