Project Profile: Achieving Silver at Brown Hall

The Colorado School of Mines located in Golden, CO, was established in the 1870s and reflects the importance of the area’s abundant natural resources in its curriculum, with courses in mining engineering, geology, chemistry, mineralogy, metallurgy, botany, math, and drawing. With this history in mind and an ingrained respect for the natural environment, the institution’s Campus Facilities Master Plan called for the renovation and new addition of Brown Hall and the surrounding hardscape and landscape to meet LEED Silver certification.

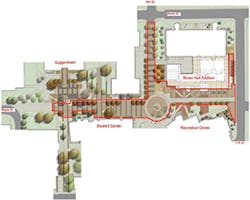

In conjunction with the construction of the new Brown Hall addition, which was built to house the engineering and mining engineering departments, the school wanted to create a beautiful yet functional pedestrian environment, where asphalt streets had previously been at the heart of the Colorado School of Mines campus. Mathew Evans, RLA, ASLA, LEED-AP, of the landscape architecture firm Lime Green Design in Denver, CO, was the project designer for this aspect of the project.

“The area around the new addition to Brown Hall had to accommodate a high volume of pedestrian traffic, and as part of the campus master plan, an adjacent street was to be vacated and pedestrianized,” he notes.

The pavement solution not only needed to accommodate the loading of emergency and service vehicles, but also to avoid exceeding historic offsite stormwater flows on the site. In addition, the pavement had to meet the campus maintenance requirements for a long-lasting, durable surface.

Evans adds, “An unanticipated second phase of the project became possible, which led to the pedestrianization of another section of street. The success of the first phase resulted in an extension of the use of the pavers in this new area. As part of the master plan, a preliminary study has identified another two blocks of city street extending out from the original Brown Hall project, which will eventually be vacated, and the plan currently shows the continued use of permeable pavers in this new pedestrian spine.”

Landscape designer Evans worked with installer JC Coniff of Rocky Mountain Hardscapes LLP and Colorado School of Mining facilities manager Bob Slavik on the selection and installation of 35,000 square feet of Eco-Priora permeable interlocking pavers manufactured by Pavestone LLC, a Uni-Group USA paver producer. The pavers complement the natural beauty of the site and met the necessary criteria for durability, with patented interlocking spacers that provide superior structural stability under loads, as well as permeability to help manage stormwater flows. The designer and contractor worked together on details such as integration of the pavers and concrete collars around utility manholes and valve covers.

The permeable pavement aspect of the project presented a number of challenges for the designer. There was an initial institutional

resistance to the use of a permeable pavement that had to be overcome. Technical challenges included slopes in excess of 8% and concerns regarding traffic loading from fire trucks, service vehicles, and the occasional 18-wheelers delivering to the site. A portion of the site has no available stormwater infrastructure, so any system used had to be designed to infiltrate the area design storms, and water could not migrate into the subgrade within 10 feet of the face of the building. Moreover, with an average snowfall of over 5 feet per year, the Eco-Priora pavement had to be durable enough to withstand snow plowing and the use of deicers. In addition, the -construction schedule was dictated by the school year so as not to interfere with students and vehicles crossing the campus.

Evans notes, “The provision of product data, other project references, and site visits, along with meetings with the design team and paver reps, provided the assurances the school needed to proceed with permeable pavers. Selection of a contractor with sufficient experience and credentials was critical to the project success, since a number of installation challenges had to be addressed in the field for a satisfactory outcome.”

Once the school was convinced of the viability of the permeable pavement system, design and construction of the project got underway. In areas where the slopes were under 5%, a typical paver cross-section featuring partial infiltration and 4-inch-diameter perforated pipe was used. Where the slopes exceeded 5%, site-specific detailing was required, including subsurface check dams and subdrains. In areas adjacent to the building, an impermeable PVC liner was included to protect the building foundation from surface water infiltration.

Aggregate materials used in the pavement cross-section were specified as ASTM #8 or #9 for the joint and bedding materials, ASTM #57 for the base, and CDOT #3 or #4 for the sub-base, which is equivalent to ASTM #2 or #3. Subgrade soils at the site consisted of mostly clayey sands. In addition, an electric snowmelt system was incorporated into the pavement design at building entrances.

Evans worked in collaboration with the building architect, Anderson Mason Dale of Denver, CO, to design a pavement pattern with charcoal bands in a tan field laid in a herringbone pattern on most of the site. A former traffic circle became the main intersection of walkways, where lighter-colored pavers were used for some of the bands in the radial pattern to meet the LEED Heat Island Effect credit.

Originally a LEED Silver certification was the goal; however, with the inclusion of the Eco-Priora permeable paver system, Brown Hall achieved LEED Gold certification. “The building addition and site was LEED registered,” says Evans, “and the paving system helped obtain the Heat Island Effect and Stormwater credits. Ideally the selected pavement system would also contribute to the LEED Regional Materials and Content credits.”

The paver colors were specifically selected to meet the solar reflectance values, allowing the project to achieve the LEED credit SSc7.1 Heat Island Effect–Non-roof. The permeable paver system also contributed to Stormwater Management Quantity Control Credit 6.1; Stormwater Management Quality Control Credit 6.2; and Regional Materials Credit 5.

The project also was the recent winner of an HNA Hardscape Award for the Concrete Paver–

Commercial/Industrial Permeable category. The HNA Hardscape Project Awards are produced by the Interlocking Concrete Pavement Institute and supported by the National Concrete Masonry Association and the Brick Industry Association. The Hardscape Project Awards recognize outstanding hardscape projects by contractors building residential walkways, patios, driveways, commercial plazas, parking lots, and streets. Entries are judged on project intent, design, quality of construction and craftsmanship, compatibility with related construction materials and systems, construction innovation, detailing, and overall design excellence.

The Colorado School of Mines Brown Hall project is intended to create a precedent for future projects on campus. By converting asphalt streets to beautiful permeable paver pedestrian-oriented areas that are also capable of supporting traffic loads, the school is embracing low-impact, sustainable, environmentally beneficial design.