Rockland County in southern New York called for major sanitary sewer interceptor projects. The county has completed its second project, which required rehabilitating a failing sanitary sewer interceptor and pipes using cost- and labor-efficient means without disrupting rail or the New York state highway traffic overhead. In addition, the project aimed to prevent future microbiologically induced corrosion.

Had the team planned to dig under the tracks and the state highway, the project would have been much more difficult and costly. Instead, centrifugally cast concrete pipe offered a more efficient approach to repairing the sanitary sewer.

“It was by no means an easy project, but the crew excelled during the course of the job,” said Dan Nuzzie, project manager for National Water Main Cleaning Co.

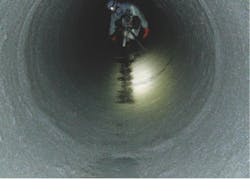

During rehabilitation, the crews had to manage multiple challenges. “The badly deteriorated existing pipeline, easement locations and heavy flow rates complicated the work,” Nuzzie said.

Crews installed parallel interceptors to divert flows, and residual flow was managed with 4- to 6-ft pumps. In addition, crews needed to work with mother nature. Rain events can cause the flow to exceed 20,000 gal per minute—and the interceptors average 150,000 gpm. The flow had to be diverted to an interceptor and eventually surcharge the system.

Finally, crews discovered a 10-ft collapsed section of pipe and an adjacent sinkhole. This required stabilizing the pipe and centrifugally casting fine aggregate cementitious composite for structural rehabilitation.

“The project is important because it allowed for the trenchless rehabilitation of a pipeline that would have been extremely costly and burdensome to have repaired in a conventional manner,” Nuzzie said.

The defects in the pipeline were addressed and repaired with minimal impact to property located above. Rail operations were not affected, and no detours were needed on the highway. According to Nuzzie, inspections have shown that the centrifugally cast concrete pipe has good adherence and is in good condition.

“Because the sanitary sewer was repaired with such minimal impact to the surrounding environment, I feel the project accomplished its goals,” Nuzzie said.

Editor's Note: Scranton Gillette Communications and the SGC Water Group are not liable for the accuracy, efficacy and validity of the claims made in this piece. The views expressed in this content do not reflect the position of the editorial teams of Water & Wastes Digest, Water Quality Products and Storm Water Solutions.