To say that Memphis, TN-based Mid-America Apartment Communities is both a landscaping and sustainability-focused company would be an understatement. The owner of more than 42,000 apartment homes in 11 southern states has had more than 60% of its portfolio recognized, with 36 landscape awards by more than 40 independent associations during the past several years, and maintains a land group consisting of regional landscape directors who manage property landscaping and its financial effects on property operations while subcontracting maintenance locally. Starting in 2005, Mid-America began incorporating smart irrigation technologies into its landscape maintenance at several properties.

The company’s use of smart irrigation is just one example of how public- and private-sector entities around the country are reducing water consumption where it is highest and most expensive—outdoors.

In spring 2010, Mid-America planned to expand its smart irrigation systems from seven to more than 20. “We started looking at some of our higher water use properties, and, obviously, the longest watering seasons that cost us the most water and money to operate are in our hotter areas of Florida and Texas,” notes Josh White, director of landscape operations. “So we started in those areas, and then realized that the technology will work anywhere we have a footprint. Now we’re trying to work it into any of our sites that use a lot of water.”

White adds that other criteria for prioritizing implementation are the cost of water in a given region and the sheer size of a community.

The smart irrigation initiative began to materialize early over the past decade. “You only have to water so much to keep things alive, but the standard in the industry for a long time has been that keeping it green means over-watering a bit to be safe,” says White. “A big part of standardizing our whole operation is teaching our vendors environmental stewardship. We wouldn’t use a system that was really expensive just for the sake of saving water if it couldn’t reduce our expenses enough to offset that cost. But another piece of it was that we noticed that over-watering was really damaging some of our plant material—we were not driving the root growth like we should have been.”

Within a couple of years, the company began to search for a specific technology provider. A major consideration was the disparate irrigation system components such as valves, lines, and output devices that were already in place; White notes that compatibility with these components was a major consideration in the choice of a control system.

A typical Mid-America system uses an ET Water smart controller—although any manufacturer’s irrigation controller can be utilized—which receives data compiled by the WeatherBug network of local weather stations via cellular signal transmission or telephone lines. The systems are controlled by ET Water’s ET Manager Web-accessible software. Regional landscape directors can enter zone-specific inputs, which, combined with the weather data and utilizing an algorithm, dictate when the system turns on and how much water is dispensed. The inputs include soil type, slope, sun/shade mix, type of landscape material, plant type, and output device; default settings are also provided. The directors tweak the inputs over time to address dynamic conditions such as root depth.

It is possible to override the system and shut it off early when an event characterized by significant foot traffic on turf is scheduled, for example. White points out that the systems also are equipped with flow sensors that alert management of conditions such as leaks or broken sprinkler heads. In addition, the system recently became controllable via smart phones. “As we travel and have access to technology, there’s the capability of having access to the Internet while we’re standing somewhere,” notes White, adding that this capability will also allow one-person control without the need to communicate adjustments to the office.

Smart irrigation fits the company’s strategic sustainability goals. Other tactics involve a Ground Cover Initiative that has reduced lawn areas by 120,000 square feet throughout its communities with plants—55% of which reportedly are drought-tolerant. The smart irrigation is expected to reduce water consumption at the properties where it is used by 30%.

White reports that smart irrigation is fundamentally changing the company’s approach to irrigation. “We’re finding that we can actually drive more efficiency by changing our landscape makeup, and we never thought about that until we saw how often the system should be running,”he says. “We see huge water uses in some areas versus others—shrubs versus ground covers, for example.”

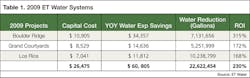

The systems are yielding tangible financial benefits, White concludes. In 2007, he reports, Mid-America implemented a total of three systems in Houston and Austin, TX. In 2009, the company spent nearly $61,000 less on water than in 2008. This represented a return on investment of 230%, versus a goal of 25% (see Table 1). “Without those systems in place, we would have been running those systems through the rain, and two days after the rain it would be running again,” says White.

Park Saves 2.5 Million Gallons Annually

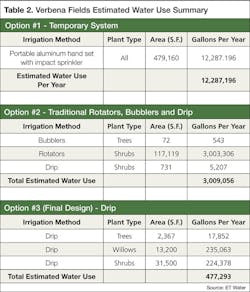

The combination of drip irrigation and smart centralized system control is allowing the city of Chico, CA, to save an estimated 2.5 million gallons of water a year, compared with a

The use of smart irrigation is just one example of reducing water consumption where it is highest and most expensive—outdoors.

traditional sprinkler-bubbler-drip system in remediating a 20.9-acre, city-owned, former gravel quarry into Verbena Fields, a natural park that recreates the site’s native habitats.

Land Image Landscape Architects, and Planners, Chico, was recognized with a 2010 Excellence in Irrigation Honor Award from the American Society of Irrigation Consultants (ASIC) for designing the system, the third time that the company and Paige Gimbal, LEED-AP, ASIC, ARCSA-AP, CID, CLIA—who since started her own firm, WaterCounts—have been recognized by ASIC.

The temporary irrigation system is scheduled to be utilized for three years, after which the vegetation is expected to reach naturally sustaining stages of growth. Additional goals of the $5.4-million project included expanding and improving seasonal wetlands, increasing floodplain width, establishing a Mechoopda Indian Interpretive Place, constructing a loop walking trail and providing public education, and post-restoration site monitoring. Specifically, the project was intended to increase the flood capacity for the adjacent Lindo Channel by adding 80 feet to the width of the flood plain, enlarging the pipe that transfers treated wastewater from the city’s treatment plant to the Sacramento River, and moving the pipe downstream by about 1,500 feet to avoid a gravel bar with the potential to clog the system. Two bioswales were also constructed to slow and treat stormwater runoff.

Construction started in the late summer of 2008 and was completed by the following March, with some final hydroseeding taking place in November 2009. Funding sources included $523,515 from the American Recovery and Reinvestment Act for wetland and riparian restoration. The remainder of the project funding comes from the city’s collected sewer fees. Sponsors included the city—which owns the land, the Big Chico Creek Watershed Alliance, the Mechoopda, Streaminders, and the Chico Research Foundation at Chico State University.

The landscape contractor, Perry Construction Co., Chico, was responsible for planting and irrigation system installation; working with Land Image and on system design and

Perry points out that the site is an old quarry, and the soils have a high content of cobble and sand, so the potential for high water use exists on the site.

Gimbal adds that, despite some skepticism among Streaminders—that point-specific drip irrigation would be sufficient to maintain willow trees on the site—she guarantees the system’s

effectiveness. She also argues that using an ET-activated system alone probably reduced water consumption by 10% to 30%.

First LEED School Cuts Outside Use

A centrally controlled smart irrigation system is a key component in the first school that was certified under the Leadership in Energy and Environmental Design (LEED) for Schools rating system. Computerization is not limited to control; however, the system designer relied heavily upon sophisticated computer modeling to minimize the system’s water consumption.

Bethke Elementary School in Timnath, CO—located near Fort Collins in the northern part of the state—is a two-story, 63,000-square-foot facility that was constructed in 2008 at a cost of $9.6 million. In addition to structural features such as a roof that can suit photovoltaic solar panels and an automation system that can be viewed on any computer in the school, the building also prioritizes water efficient landscaping.

The project irrigation consultant, Aqua Engineering Inc., Fort Collins, CO, received an Excellence in Irrigation Honor Award in Commercial and Public Works from ASIC. Additionally, the project received a LEED Gold Certification and three Green Globes from the Green Building Initiative in 2008. The facility also became the first school in Timnath to utilize nonpotable water for public area irrigation.

Bethke Elementary, located at the center of a new housing development, was designed to achieve highest LEED certification possible from the outset. Aqua Engineering was charged with providing a high-efficiency irrigation system design for turfgrasses, perennial beds, and plant materials on the eight acres of grounds surrounding the school. The firm wound up developing a central control system with an integrated weather station for automatic response to daily ET rates.

The system consists of 115 Rain Bird PESB remote-control valves, 214 Rain Bird 7005 pop-up gear-driven rotor sprinklers and 214 Rain Bird 1804 pop-up spray sprinklers and bubblers. A Motorola IRRInet controller, used for irrigation control, is linked to the school district’s central control computer that receives daily ET information, and run times are adjusted accordingly. The system’s pump station is designed for 250-gallon-per-minute (GPM) total output using two 125-GPM variable frequency drive motor-operated pumps with a 300-micron automatic flushing filter.

J. D. Leonard, project designer for Aqua Engineering, notes that water conservation played a significant role in the overall motivation for achieving the environmental certifications. Leonard points out that water is in high demand in the Timnath region, and, in recent years, water restrictions and water rights issues have become nearly as prevalent as in the desert Southwest. He adds that Aqua Engineering already had some experience with obtaining LEED credits on its projects.

A key feature of the system is the fact that it uses raw water. The water flows down from the nearby Rocky Mountains and is collected in an irrigation ditch, located about half a mile north of the Bethke Elementary site, which was primarily constructed for agricultural use. The basis of a pipe network is already established in the surrounding development. Some modifications had to be made to the system to accommodate raw water, Leonard notes. A filtration system was installed in the pump station and Aqua Engineering ensured that the remote-control valve assemblies were set to accommodate the filtered feed water. Finally, he says, drip irrigation—which can cause plugging and biological slime or sediment buildup—was not used.

Leonard reports that the use of Bentley WaterCAD software for designing the distribution network allowed Aqua Engineering the opportunity to value-engineer it. Aqua Engineering entered data such as water source and elevation changes, which affected pressure, and was able to utilize 3- or 4-inch, as well as 6-inch pipe. “The program helped us to determine where those break points were, so that we could save materials, and also save some money for the owner, and still have an efficient system and deliver the pressures that we needed,” says Leonard.

Sprinkler selection was also aided by the use of a program called Space Pro from California State University Fresno’s Center for Irrigation Technology. The software contains information on various sprinkler designs’ performance attributes and Aqua Engineering used the data to determine sprinkler spacing, the right pressure, and the appropriate sprinkler-nozzle combination and calculate the distribution rate. According to Leonard, the program also helped Aqua Engineering to program the controllers through the use of a scheduling coefficient. A perfect coefficient of 1.0 indicates that 1 inch of irrigation is needed for every inch of rain. “There’s a lot of central control out there, but if the central control doesn’t get the right input to begin with, and it doesn’t have the right baseline to begin with, it’s a big alarm clock that’s turning the system off and on, but it’s not necessarily saving water,” says Leonard.

Optimizing water use is critical at a school where the students are involved in many outdoor activities and sports on the grounds, Leonard points out. “It’s quite a challenge to get everything watered in between the times when we’ve got children on the playground,” he says. “It’s not just using the water efficiently, but also using the watering window efficiently and giving it only the time it needs.”

Due to both the use of smart irrigation and low-water and no-water plant materials, the water savings versus baseline is 61%, compared with a minimum of 50% per the LEED certification criteria, Leonard says. Peak-season daily water savings is about 41,000 gallons, he concludes.

Winery Saves Water, Bucks

Bronco Wine Co., Ceres, CA, is best known for selling a Charles Shaw-branded wine nicknamed “Two-Buck Chuck” through Trader Joe’s gourmet grocery stores. The company’s irrigation efficiency probably will not thrust it into the consciousness of mainstream America to the same extent, but that seems to be OK with Steve Harrow, corporate agronomist. He’s more concerned with ensuring plant and grape quality—with minimal water use—from behind the scenes.

Harrow explains that Bronco Wine experiments with various soil moisture sensor designs at more than 70 ranches comprising about 35,000 acres. Such site-specific technological tweaking is in addition to leveraging human know-how, he says.

“Our irrigators are out there with probes, poking holes in the soil, or by feel, getting a sense of where the water is, checking visually on the vines to see if the tendrils are upright and growing,” says Harrow. “That’s the low end, which is a really important part of what we do. On the other end of the spectrum is the high-tech end where I can get online and look at real-time graphs of our moisture sensor sites that show me volumetric water at 12 inches, 24 inches, and 36 inches, which are set based on the soil texture, type, and horizons.” Harrow adds that the company is trying out moisture probes from PureSense and Ranch Systems that provide readings at various depths.

Harrow and Bronco Wine use multiple Web-based systems for monitoring the ranches, too. The ECH2O system from MorpH2O Water Management LLC transmits signals via radio. Systems from PureSense and Decagon Devices transmit data via cellular modem.

“At certain depths, depending on the soil itself and the various horizons, we’ll have a sensor at multiple depths so that I can look at one site, and I can see the interaction of the water level at, say, 12 inches versus 18 or 24,” says Harrow. “So as we get a rain event or an irrigation event, I can actually see the water moving down through the profile and also the actual water volume at each level.”

Bronco Wine is looking at the various technologies because “We’ve always been a company that asks why and doesn’t just do the same things over and over,” says Harrow. “We’re constantly looking at different research areas with different products, materials, and techniques—not only in the area of water.”

Still, smart irrigation is a relatively new concept for Bronco Wine, one that has emerged in just the past few years. Harrow brought experience with the ECH2O and Decagon Devices systems with him from a stint as a regional agronomist with a chemical company. Bronco Wine still depends greatly upon a staff of irrigators to monitor plant conditions, but Harrow describes the technologies as a final check on potential over-watering. The company adopted the technologies because it is available and affordable.

Harrow indicates that, to date, the ability to fully quantify water savings has not yet occurred. “We have a saying that you can’t manage something until you can measure it,” he says. “This technology definitely allows us to measure what’s in the soil, but we’re also putting in flowmeters, and wireless telemetry will allow us to accurately measure how much water we’re pumping and at what times, and monitor our pumps and motors for efficiency. Now that we can measure, then we can monitor, then we can manage.

“At the end of the day, we are a business,” he adds, “and we have to attach a monetary value to all of the things we’re doing. Are we putting the right amount of water on at the right time? What’s the cost of the water sources? Are we watering at off-peak times? All of these things come together to make us more profitable but also a better steward of the resources.”

Bronco Wine’s operations have not been completely automated, which is fitting for the winemaking business, Harrow says. “Irrigation is definitely similar to winemaking—there’s a science to growing grapes, but even with something as precise as irrigation, there’s an art form there, too—that’s where the guys on the ground really come in.”