It’s not unusual for most water districts today to rely on Supervisory Control And Data Acquisition (SCADA) systems to control and monitor the way they deliver water to their customers.

But for David Lee, director of global business development for Warrendale, PA-based Siemens Water Technologies, this widespread acceptance of SCADA systems doesn’t mean that new developments aren’t taking place in the automation industry. In fact, Lee argues that just the opposite is true.

During the last five years, municipalities and water utilities have turned to their SCADA systems for higher-level applications, relying on them to determine times of peak water use, identify potential system leaks, and even help them set their billing rates. And this change is allowing utilities and municipalities to reduce their operating costs and deliver water more efficiently to the residential and business customers in their service areas.

Best of all, this is a trend that Lee doesn’t see slowing any time soon. “The idea of SCADA is hardly new; it’s been around for 20-plus years,” says Lee. “What I’m seeing now, though, is a greater number of water districts are turning to SCADA to help them reach optimum efficiency. They’re using SCADA to cut costs and manage their energy usage. They are using it to study water-flow data and detect leaks more quickly. They are using SCADA for anything that can help them use less energy and produce more water. To me, that is the exciting news regarding SCADA.”

And Lee is hardly alone. The professionals who work in the SCADA field–promoting it, fine-tuning it, and creating the computer and software systems on which municipalities and water utilities are increasingly relying–echo Lee’s statements: SCADA users are turning to this technology for a wide variety of functions. And all of them are designed to reach the same goal: reduce costs and make water districts more efficient.

There are even a growing number of companies that are offering products that either act as alternatives or complements to SCADA, products designed to boost efficiency at water utilities at an even faster rate.

The world of SCADA, then, is a changing one. And the hope among the people working in it is that it’s one that will provide a host of benefits to municipalities and water districts that need to do more on ever-smaller budgets.

Weak Finances Are the Key

The nation’s weak economy has placed new pressures on municipalities. As their budgets shrink, they’re struggling to serve their residents as efficiently as ever, even as their financial resources ebb.

This has caused municipal officials to get creative. And when it comes to delivering water, much of that creativity lies in tapping more of the power of SCADA systems.

“The pressure is so great today on municipalities,” says Doug Johnson, Director of Marketing with Emerson Power and Water Solutions. “They have to resolve so many problems today in the wake of the funding issues they face. Automation systems are a way to do this. If used properly, municipalities can use them to operate more efficiently and cut costs. And that’s something every municipality needs to do today.”

Johnson points to a recent survey from the American Water Works Association. This survey showed that some of the biggest water-delivery problems facing municipalities are financial ones. According to the survey results, water district officials are too often scrambling to find the funding they need to safely deliver water to their customers.

Users are turning to SCADA for a wide variety of functions.

“Generally, business issues were the top things on this list,” says Johnson. “Many water districts are struggling with infrastructure problems. We see a lot of crumbling infrastructure, especially in the Northeast and Midwest parts of the country. There simply is not enough money. At the same time, the financial support from the federal and state levels is falling because of the bad economy. The municipalities have to fund more of the capital projects themselves to keep their infrastructure running. Anything they can do to save money is a big help.”

At its most basic level, SCADA offers end users a way to automatically control various systems, including water-delivery systems. But municipalities that don’t push beyond this basic level of SCADA are missing out on the true benefits of automation.

Johnson points to the energy-management benefits that SCADA systems can bring to water utilities. Some of the biggest energy drains in water systems are the pumps that move water through pipes. When pumps begin to degrade, a natural occurrence as they age, they require more energy to do their jobs.

SCADA control room console layout

Using SCADA systems, though, officials with water districts can monitor how efficiently their systems’ pumps are operating. With the help of data from their SCADA systems, they can measure the efficiency levels of their pumps against normalized operating curves, something that lets them identify when pumps are starting to falter. Officials can then consider whether the energy efficiency jump from purchasing a new pump will be significant enough to cover the hefty expense of purchasing new equipment.

Municipalities can also use the data provided by their SCADA systems to help protect their infrastructure and prevent it from degrading significantly in the first place. Through online data analysis, officials can determine if expensive equipment such as pumps and blowers are starting to perform less efficiently. Rather than wait for a breakdown, or for the equipment’s efficiency levels to fall even further, district officials can schedule emergency

maintenance.

“Maybe a municipality was planning to take a certain piece of equipment down in three months for maintenance,” says Johnson. “With SCADA, a municipality can determine if a problem is taking place earlier. The municipality can save a significant amount of money by fixing the problem earlier, before it becomes more costly to repair.”

SCADA can help municipal officials save money in the opposite direction, too. Maybe a blower is scheduled for repair in two months. The data provided by SCADA may suggest that the equipment is still performing at peak efficiency as that scheduled maintenance date approaches. Water officials might then decide to hold off on costly maintenance because the blower is performing so well, again saving their municipality some significant dollars. Such a move might even free up enough dollars for a water district or municipality to spend on a different water-improvement project.

All of these cost savings help both the providers of SCADA systems and the water-utility officials who have to work with budget-conscious city and town boards. Water utilities are more willing to purchase SCADA systems and upgrades if they know these purchases will eventually save them money. At the same time, municipal boards and councils will be more willing to allocate the money for these purchases for the same reasons.

Selling Costly Systems in Tough Times

For all their benefits, there is at least one significant problem with SCADA systems: They’re not cheap.

And in today’s world of tight budgets, that can be a problem for water utility officials who wish to purchase these systems or upgrade ones that are becoming obsolete.

The manufacturers and distributors who sell these systems know this. It’s why when they attempt to sell them to municipalities they focus so intently on the annual savings–in time, labor, and energy costs–that SCADA systems can provide.

City of Dunedin RO water treatment plant

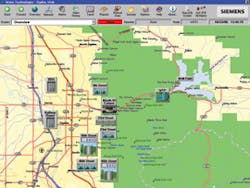

Screen showing level of Ogden, Utah 46th Street reservoir.

“Many municipalities do get it. They understand that the savings they’ll receive from SCADA can really help the bottom line of their department,” says Lee. “If we can justify the savings, if we can prove to them that the savings each year are high enough to allow them to cover the cost of the project, we are far more likely to close a sale. If we are able to show them that the return on their investment is high enough each year so that they can quickly overcome the initial hurdle of coming up with the upfront costs, we can usually convince municipalities to purchase our system. If they can see that the product comes with a short payback period, they’ll usually embrace it and move on.”

Kip Edgley, director of automation and integration with Veolia Water, says that selling SCADA systems and software becomes less challenging, even in these difficult economic times, if manufacturers can show water utilities just how much money the systems can save them over their life spans.

Edgley says that municipalities can best achieve these savings when they can more easily understand the information that SCADA systems are providing them.

That’s why Veolia focuses on providing an easy-to-read graphical interface with its SCADA products. This way, engineers for water districts can quickly see when equipment is underperforming, whether their system has a possible leak, or if demand is spiking at an unexpected time of the day.

By communicating this information quickly and clearly, Veolia’s SCADA system is able to tell utility operators if their system is experiencing a problem that could turn costly if not treated quickly. This can result in significant savings throughout the year, Edgley says.

“No matter how many features or extras that a SCADA system has, if it is not capable of effectively presenting information and working in an interactive way with an operator, it is not going to be particularly effective,” says Edgley. “If the system does not do a good job of presenting information, there is an inherent decrease in efficiency right off the bat.”

As an example of the way reliable data presented clearly can save end users a significant amount of dollars, Edgley points to the high energy costs associated with operating water pumps. By analyzing the data they collect from their SCADA systems, engineers can determine if their water system’s pumps are demonstrating a high amount of flux current. This is important; the more flux current a pump experiences, the less efficiently it is operating.

Utility operators can then reconfigure the programming of their water-distribution system so that their water pumps will stay in the “sweet zone”–where there is little flux current–for

a longer period of time. This change can result in a system that pumps out more water for fewer kilowatt-hours, Edgley says.

Edgley points to the widespread acceptance of Ethernet-connected SCADA systems–which allow water district operators to quickly scan multiple levels of data from their water systems instantly–as a key advancement that has led municipalities to higher-level SCADA use.

“What is the major development in the past five years that has made the most difference when it comes to SCADA systems?” asks Edgley. “The acceptance of industrial Ethernet systems is the answer 99% of the time. When water utilities accepted that protocol, it changed the face of the SCADA industry dramatically. The options for manufacturers, users and providers changed in a significant way.”

Some of the savings that municipalities can experience when they use SCADA at a higher level can be dramatic. What if an expensive piece of equipment, such as a centrifugal pump or blower, fails abruptly? The costs to repair these pumps are tremendous, Edgley says.

But what if district operators discover through irregular data patterns that these pumps or blowers are starting to operate erratically? What if they discover that their efficiency levels are plummeting?

Operators, after analyzing the data, can order preventative maintenance on the equipment before it breaks down. It’s far less costly to maintain blowers and pumps than it is to perform emergency repairs on them, Edgley says.

“With SCADA today, operators can bring in data in a more efficient way,” says Edgley. “The high-level functions of SCADA make it an easier sell. We can demonstrate just what the data can mean to a municipality that needs to save money. Providing municipalities with this information can make a big difference.”

An Aging Workforce?

But a dismal economy isn’t the only hurdle that manufacturers face when they are trying to sell SCADA systems or upgrades to existing systems. They must also deal with a workforce that is consistently getting older.

And sometimes the members of this aging workforce aren’t eager to take on the challenge of dealing with new SCADA technology.

“The people working for municipal water districts, by and large, are not getting younger,” says Lee. “They are often uncomfortable with adapting to new technology. That can sometimes prove a significant challenge for municipalities. How do they upgrade to more advanced SCADA software when much of their workforce isn’t comfortable using it?”

Fortunately, there are solutions to this. Many manufacturers offer their own training on how their SCADA systems work. Municipalities can ease the concerns of their water district employees by ensuring them that they won’t force them to operate new systems until they’re fully trained on how to use them.

Other manufacturers make sure that their systems are intuitive enough so that an aging workforce won’t struggle to understand how they work.

That’s the approach that Siemens Water Technologies takes.

“One of the ways to get around this hurdle is to use interfaces that water district workers are already familiar with,” says Lee. “We use technology that they are already comfortable with in other areas in which they work. It’s user-friendly, and it makes the systems far less intimidating to workers.”

Johnson, from Emerson, says that the engineers with his company spend a significant amount of time with clients to train them on how to best use their SCADA tools.

The key is to show end users that SCADA is intuitive, that it isn’t something that will require weeks of intensive study to master.

“We spend a lot of time with our customers showing them that the SCADA systems of today are not that difficult to learn how to use,” says Johnson. “We all face this issue with our computers and cell phones. We know that eventually these tools will become obsolete, and we’ll have to move on to the next technology out there. We are teaching our clients that it isn’t this way with SCADA. It’s not the normal kind of tech replacement that they have experienced in decades past. It doesn’t require a rip and replace of their existing system. The upgrades now can come in small doses over time. They don’t require that users start from scratch.”

Supplementing SCADA

Despite the advanced ways in which operators can use SCADA systems, not everyone thinks that SCADA alone can truly help municipalities and water district boost their efficiencies.

Count Timothy Hicks as a member of this group.

Hicks is president of Seattle, WA-based FlowWorks, a company that sells a host of online data collection, monitoring and analysis tools. These online tools allow the operators of municipal systems, including water distribution, to determine how efficiently their systems are operating. Users can detect possible leaks by studying the water-use data FlowWorks presents. They can also determine peak usage times and monitor the effectiveness of their aging equipment.

Hicks says that SCADA is important for users who need to control the operation of pumps and blowers. But systems such as FlowWorks, he says, are more effective when it comes to the presentation and analysis of data. Systems such as FlowWorks are also less expensive than are full-fledged SCADA systems, he says.

He recommends municipalities and water districts use a combination of SCADA and online data-analysis tools to best manage their water-delivery systems. The online tools can draw data from SCADA systems and present them to users in an easy-to-understand format.

Hicks also says FlowWorks can send the data that it collects into municipalities’ SCADA systems.

Grant Van Hemert, application specialist with Schneider Electric, is another proponent of supplementing SCADA with online automation tools.

His company manufactures AMPLA, an online operational data management system that allows municipalities and utilities to quickly access data from their water systems.

Used in combination with SCADA systems, online data tools can help districts boost their efficiencies. SCADA on its own is a very powerful tool, Van Hemert says. But when it’s used in combination with online data software, SCADA becomes a means of providing users with the information they need to isolate problems, trends and peak-usage times.

Operators can use this information to spend less money when delivering water to their clients, he says.

“There’s a great analogy that I always use: SCADA is a great tool for turning on and off pumps and for basic trending and historical data,” says Van Hemert. “If you have a period of five years and you want to know for a given pump station what the minimum, maximum and average flow were for that five-year time, SCADA can deliver that information to you in a second. But if you want to know when that pump station was at a minimum or maximum flow, or when it was at its average flow and for how long, that is a data set that SCADA isn’t set up to give you.”

Water utilities are turning to SCADA for a variety of higher level applications.

SCADA systems may tell operators what their peak water flow was for the month of August. But by supplementing SCADA with an online data-acquisition tool, one that dives into a municipality’s SCADA system and pulls out operational data, municipalities can determine that their peak water flow happened at 9:30 a.m. on Aug. 15. Municipal officials can then determine if that information is relevant. Maybe there was a major water leak at the same time that the system experienced its peak water flow.

An operational data management system, then, can help water officials determine if peak water-flow data for a specific month is really indicative of increased demand or a one-off incident.

“A SCADA system is like a ship with a weather station outside the bridge,” says Van Hemert. “An operational data management system is like having the weather station’s historic data with you so that you can predict future weather events. It gives you an additional layer of information to help you in making your decisions.”

With the use of an operational data management system, end users can eliminate the monthly peak-flow numbers that occur during a pipe leak, he adds. They can then analyze the numbers that remain to gain a truer understanding of when demand for their water was truly at its height during the month.