Water Treatment Options and Uses of Treated Water

There was a period some years ago when I was closely involved with projects concerned with water and wastewater, especially the pumping, and I was frequently amazed by the number of municipalities and property owners who told me stories of systems to purify their water that had suddenly failed or been found to be less than promised.

We can hope that most of the get-rich-quick cheats with strange chemical and other allegedly scientific systems have vanished into obscurity now, but I must still caution everybody to be wary of solutions that seem too good to be true, because they may be just that. Nevertheless, this article does not take a negative view of water treatment. Quite the opposite. There have been some solutions for contamination going for years with few or no problems, and we should certainly not reject them just because something new has appeared. But, we should investigate new technologies in water treatment, because, simply put, they may be better, more sustainable, and even less costly in the long run.

The cost always comes into the equation. Back in 2006, EPA released the Long Term Enhanced Surface Water Treatment Rule (LT2 rule). The LT2 rule requires surface water treatment facilities to either filter their water, or install an extra barrier for microorganisms, in what we can call a multi-barrier disinfection strategy. At one of the largest projects for water treatment (the Catskill/Delaware in New York), engineers looked at the cost of installing a filtration system for the 2.2-billion-gallons-a-day facility and found it would be considerably more expensive than alternatives. After thorough research into the available technologies, the authorities decided that the most practical and cost-effective solution to meet new rules would be utraviolet (UV). TrojanUV was chosen.

UV has been proven to be a safe solution for primary disinfection; one reason is that it is free of the potentially harmful byproducts associated with chemical disinfection, and it doesn’t affect the color, odor, or taste of the water. At the Catskill/Delaware UV Disinfection Facility, Trojan supplied 56 units, able to treat the more than 2 billion gallons per day. (Trojan has similar, large-scale experience worldwide.) The innovative UV systems can also be integrated with existing chemical disinfection treatments to meet regulations that protect our public’s drinking water. As for the cost of UV disinfection, reports indicate that it costs, typically, about one-fifth of what ozone disinfection costs, and one-tenth the cost of membrane filtration.

At the New York facility mentioned above, the UV units neutralize all waterborne pathogens for the drinking water that comes from the city’s major sources: the watersheds of Catskill and Delaware County. The UV adds that additional barrier required by law by adding to the chlorine treatment that the region has used for years. It provides protection against Giardia and Cryptosporidium; symptoms of infection by these microorganisms can include nausea, cramps, diarrhea, and more serious ailments.

For those who think all EPA decisions are ridiculous, these that protect our drinking water make good sense for everybody in the community. Chlorine has done good service for years, but neither chlorine nor UV treatments can manage all threats to drinking water on their own. Cryptosporidium can resist chlorine well, but will be inactivated by low doses of UV. By contrast, adenovirus resists low-dose UV disinfection, but can be killed by chlorine. Adenoviruses can get into water sources from human fecal contamination, such as septic tank effluents. If you have septic tanks being discharged into your water sources, perhaps entering the reservoirs, adenoviruses need to be monitored and avoided.

It is important to emphasize that the new regulations mentioned address surface water, which is often contaminated by animal and bird activity, as well as by anything human. Many communities rely on groundwater, not surface water. It should also be noted that an increasing number of UV systems are now validated to provide the UV doses required to inactivate viruses, including adenovirus.

Technologies Advance

Celebrating 30 years of profitable business, Aquionics can claim to be a leader in the successful use of UV disinfection. The company does not concentrate on any particular segment among the sectors benefiting from UV science and technology, and has worked with municipalities, cities, consultants, as well as with some of the biggest companies in the beverage, food, electronics, aquaculture, pharmaceutical, and leisure industries. This broad experience has contributed to the knowledge that the company engineers have about the needs and necessities of different clients.

Basically, Aquionics uses powerful lamps to produce concentrated UV radiation that destroys microorganisms. It’s like that sunshine we love so much. Strong sunlight makes biological impurities inactive, permanently; so do UV disinfection systems. Water plants across our continent are using UV technologies, and there is growing momentum. Apart from treating those chlorine resistant pathogens like Giardia and Cryptosporidium, UV systems can alleviate safety concerns about the transport and storage of chemicals, and reduce the generation of disinfectant byproducts. Possibly more relevant in today’s economically battered communities, UV systems can bring both capital and operating cost savings. The UV-Pearl is one of the latest offerings from Aquionics; it’s the world’s first UV-C LED Disinfection System.

Not all water treatment is for large community systems. The PearlAqua has a compact design and uses UV-C LEDs for the disinfection of water. Its size and features make it a good product to integrate into other water treatment systems or to stand alone as a disinfection system. Among applications for this compact product, you will find it integrated into OEM devices, for laboratory research equipment, for health care equipment and clinical pure water applications, for endoscope repressors, and for other washing and rinsing needs. It has third-party microbiological verification according to EPA guidelines.

Not All Water Is for Drinking

We tend to think of clean water as something to drink, because the purity of potable water is essential to healthy living. Just how little of the water that has been cleaned will be drunk by people might surprise most of us, but the water used in other areas of our daily life should also be clean. Take the water in cooling systems, for example. There are many threats to the efficient and cost-effective operation of cooling systems, among them corrosion, scale, fouling, and biological growth. All these menaces can debilitate the cooling system and increase its costs dramatically.

Nalco has been active in water treatment for many decades, and one of its products, known as 3D Trasar technology, has been especially successful in managing the water in cooling systems. Thanks to real-time monitoring and control technology, 3D Trasar detects the often-unseen menaces that come before obvious problems such as corrosion and scaling, and then delivers the suitable chemical response to their attacks. This results in less maintenance of your cooling system, lower operating costs, and avoidance of overdosing or underdosing of chemicals. These advantages mean better protection for your assets.

Monitoring and maintenance of treatment systems

Treasure Island Hotel and Casino in Las Vegas, NV, offers an example of how the right solutions have helped owners of buildings with cooling systems. At this hotel, the ability to automatically increase cycles of concentration when the risk of deposition was low, and decrease cycles when scale potential increased, brought savings of thousands of dollars in water costs in the first six months the hotel began with Nalco’s 3D Trasar. (Even though the average temperature during the period was 8% higher than normal.)

At such a site, maintaining a constant biocide concentration results in periods of over- and under-treatment. Over-treatment wastes money; under-treatment allows biopopulations in the cooling system to grow and to form corrosive biofilms–this may well create environmental and health concerns for clients. 3D Trasar Bio-Control measures actual bioactivity and applies biocides as needed in response.

One method that has proved successful in many places is Dolphin WaterCare (from Clearwater Systems Corporation), which has provided environmentally responsible water treatment solutions for over a decade. Known as The Dolphin, this patented technology has more than 5,000 installations worldwide so far. Dolphin WaterCare is a chemical-free process that successfully treats the water for cooling towers, fluid coolers, HVAC and process chillers, ammonia condensers, and process heat exchangers. A good example of its merit would be for the way it helped Verizon Wireless win a Green Enterprise IT (GEIT) Award from the Uptime Institute. The award recognized the combination of resource efficiency, environmental responsibility, and scalability in the building of a Tier III, LEED (Leadership in Energy and Environmental Design) Gold-certified data center in Twinsburg, OH.

“We were delighted to be part of Verizon Wireless winning this prestigious award,” comments Anupam Bhargava, CEO of Clearwater Systems. “It’s further affirmation that our water treatment solutions are dramatically helping customers improve the sustainability of their operations.”

In that data center, Dolphin WaterCare was installed in the cooling system to treat a maximum cooling load of

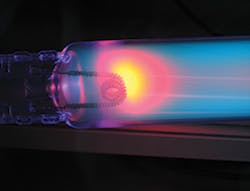

A UV system working on wastewater treatment

approximately 2,600 tons on this mission critical application. Use of the system results in a water discharge reduction of more than 20% (1.6 million gallons), compared to the discharge from chemically treated water. The clean Dolphin technology provides the Twinsburg Data Center with an opportunity for water reuse. By using the discharge water from the cooling tower, graywater applications such as landscape irrigation can be implemented. Given the chemical-free operation of Dolphin WaterCare, this Verizon Wireless facility also avoids the cost, use, and storage concerns associated with waste generated by the use of typical chemical water treatments.

360 State Street in New Haven, CT, was built in 2010. It’s a mixed use/residential skyscraper that has quickly become a landmark in the heart of the city. As one of only a few buildings in Connecticut to achieve LEED Platinum status, it is setting the tone for sustainable living in New Haven. The challenge was to improve the safety of the facility, water efficiency, and economic performance. The facility has an impressive array of sustainable features, including green vehicle amenities, alternative energy fuel cell technology, rainwater recapture, green roof, advanced energy monitoring, and optimization.

Despite those progressive features, the facility was still relying on chemical-based water treatment for its cooling water. That exposed the building and its occupants to the risks associated with chemical water treatment. The team at 360 State Street decided to remove the hazards of chemical water treatment, while also earning extra points towards LEED certification.

“While LEED points were a driver for our choice of Dolphin WaterCare, the benefits we have seen go much further,” observes Bruce R. Becker, AIA, AICP, 360 State Street Developer. “Our water use is significantly lower, our HVAC system is in excellent health, and 360 State Street is an even safer facility as we have eliminated chemicals for cooling water treatment.”

An Old Favorite

Spartan Environmental Technologies offers ozone water treatment as its primary solution and has had great success in industrial, commercial, and municipal settings. The company explains that: “Ozone is a powerful oxidant and disinfectant that acts quickly at low concentrations in many water purification applications. Ozone’s oxidation power can be further enhanced by combining it with peroxide or UV to create advanced oxidation processes.”

Dolphin WaterCare treatment systems can be located inside or outside.

Ozone breaks down into oxygen after it has completed its role as an oxidant or disinfectant; that minimizes any negative environmental impact. The storage of chemicals (and the potential dangers associated with that) is eliminated, because ozone is generated onsite, by an ozonator. After more than a century of development and use, ozone generators today are most reliable and economical, a technology approved for drinking water treatment by EPA. It is one of the strongest disinfectants approved for potable water treatment and has been shown to be able to inactivate viruses, bacteria, giardia, and cryptosporidium. (I remember as a small boy going to the seaside and hearing my parents exclaim with relish “Smell that ozone!” as we drew near the sea, as if it were a cure for the smog and dirt of the big city where we lived. And, you know, I did feel better.)

For the treatment of drinking water, Spartan offers ozone generators and associated equipment. The capacity of the equipment can reach 1,320 pounds per day. Depending on the application, the biggest units can treat up to 40 million gallons per day of water. Used for more than 40 years and in hundreds of installations, ozone for water treatment has proved itself reliable and effective. If you have drinking water systems with needs for disinfecting, removal of manganese or iron, and control of taste and odor, you could benefit from ozone systems. There are more than 250 drinking water plants in the US that use ozone, including such cities as Detroit, MI; Los Angeles, CA; Tampa, FL; and Dallas, TX. As a small, but practical, bonus, many plant operators have discovered that they have been able to reduce coagulants/flocculants by 20% to 50%.

In operation, large-scale ozone generation must be done onsite, from either oxygen or air, with the basic steps being feed gas preparation, ozone generation, cooling, ozone contacting, and decomposition. If you use air as the feed gas, it must be dried to a dew point of -70°C (-94°F), advises Spartan. This is most often done with pressure swing adsorption operating at about 100 psi. Or, oxygen can be concentrated from air using similar technology, but at higher pressures.

The final approach (usually used in larger applications) is to use LOX (liquid oxygen). Ozone generation from LOX is said to be more efficient than from air. Practically, the choice of feed gas is based on the LOX price, energy, and capital costs for each approach. Most ozone generation in drinking water treatment is done today with the corona discharge method, a process in which the feed gas is passed through an electric arc or plasma where part of the oxygen is converted to ozone. (The typical configuration is similar to a shell and tube heat exchanger.)

A company that has respectable experience in oxygen supply for such diversified industrial sectors as smelting, aquaculture, and gasification, as well as for ozone production, water purification, and wastewater treatment is Adsorptech. The company’s EcoGen Oxygen VPSA can bring low cost, high reliability and most important, a flexible oxygen supply to maximize your production and give you a good return on investment. The oxygen is produced at your site, so you have no problems with transportation and shipping. Perhaps more importantly, use of such equipment can eliminate the problems caused by disruption of supply when you rely on products produced offsite.

EcoGen VPSA systems come in sizes from 1 to 12 STPD, nominal 20 to 200 SCFM, at an oxygen purity of 90% ±3%, and supply pressures up to 5 psig and 15 psig as standard designed products. Higher psig models are available, but the cost of production also goes higher in those instances. Adsorptech’s patent-pending Ecogen technology offers a good combination of low power consumption and high reliability. The company claims the VPSA system is nearly twice as power efficient as alternative oxygen PSA systems available today. Ecogen has a process design that, when any primary separate component fails or requires shut down for repair or maintenance, the system can operate at about half its design capacity. Such an operating benefit reduces the user’s reliance on high cost alternative oxygen sources. The Ecogen requires neither cooling water nor seal water, further indication of the system’s avoidance of those problems associated with requiring such utilities.

Aspects of Ozone Generation to Consider

Corona discharge was mentioned above. It is sometimes perceived as competitive with UV Ozone. There are several technologies promoted for corona discharge ozone operation but, basically, they all involve passing gas containing oxygen through an electrical field. The electrical current causes the breakup of the oxygen molecules, similar to the process of UV ozone generation. The electrical energy sent to a corona discharge ozone generator generates heat, so the user needs some way to remove that heat. That need is magnified because an ozone generator relies on good cooling for its efficiency; water and air are the most popular coolers.

Those who favor corona discharge ozone generation will say that using oxygen preparation can double the output per given volume (versus dry air). The infrastructure or construction required for the corona discharge method is small, which can make its installation more acceptable in water treatment plants with space challenges. Some say that the ozone created is more pure and that it doesn’t make any other harmful or annoying gases; it is also capable of making 100 pounds of ozone per day, and a corona’s cell life can be greater than 10 years. The people who consider corona discharge ozone generation the best deal are quick to point out that production is greater than UV ozone generation, but that will depend on the number and size of UV bulbs used. Perhaps the biggest criticism of UV ozone generation is that it requires more electrical energy to produce a preset quantity of ozone than does corona discharge.

We’ll have arguments whenever technologies collide and compete, whatever our industry sector. From reading many pages of facts and opinions about water treatment, I have decided that, often, both sides of an argument are right, in some aspects. When the proponents of one technology belittle the competitive technologies, it is usually to promote the products or equipment they are selling. That is perfectly understandable. Everything points to the need for reliable education, of those who run the water treatment plants, and of the people who use the treated water. At this time, when you read of the many people who don’t think there is a real water crisis, the plant personnel are closer to the actual day-to-day issues and are the most likely to see the benefit in learning about helpful new–or even old–technologies. Whether we use UV or ozone, or a combination of both, our most difficult task is to educate our customers on the need and unavoidable cost of producing water they can drink safely, water they can use for their business or personal needs. There is no new water, is there? We use it, abuse it, and it keeps coming back. Well, it has done so, so far. With one technology or another, we can continue to provide our public with the clean water it must have. But we must do something about how that water is consumed.