Anyone who’s worked with a containerized plant has seen evidence of how strong plant roots can be. Adhering tightly to the soil, roots form a living net of fibers that often require a sharp knife, or ax, to rend. Of course, with any erosion control project, plant materials (especially those with fibrous roots, rather than taproots) are always a key component; however, many in the industry argue that plants can do much more of the work expected-and that a copious amount of hardscaping is not required.

Soil conditions determine what remedies will be used. Hardpan or dense clay soils resist vegetation at any level; getting something to grow on a sloped site where heavy rains wash through is next to impossible. In such cases, liberal use of concrete, rock-filled gabions, and retaining walls might be the only workable solutions. But other soil types, or those which can be improved by adding organic materials, will promote growth; and greener, more natural solutions can be found.

The soil pH should be adjusted for optimal growth. Most plants prefer a neutral-range pH (6.5 to 7.5), because such a pH allows plants to make use of the nutrients in the soil. Soils that are too acid or too alkaline don’t allow nutrients to chemically bond with plant roots. Changing the soil pH is not always feasible; a bit of lime will help make the soil less acidic, and one can lower alkalinity with aluminum sulfate and sulfur, but as many projects are time- and cost-sensitive, such reworkings are not always done. Instead, plants that will tolerate less-than-optimal conditions are chosen, or more hardscape is added. However, hardscape can also present problems.

Too Hot for Growth?

Although, over eons, nothing is totally impervious to water, concrete and rock resist quite well. Both components are especially effective at the bottom of a slope, not only to serve as a “footer” or foundation for subsequent erosion controls, but also as a “wave break,” a strong defense against moving water’s scouring power. Yet, because concrete and rock tend to retain solar heat, sometimes plantings within them will wither and die. However, if the hardscape is bathed in water, this effect may be lessened. As taller plants are usually placed above the footers, their shade may allow inter-plantings to grow.

In addition, concrete and some rocks can leach chemicals; concrete can make soil more alkaline (leaching lime), and rocks can often contain elements that wash off with a lower pH. With these factors in mind, some firms are striving to use more plant materials and less hardscaping in water-flow projects.

The Earth Moves

Perhaps “holding back change” is erosion control’s most difficult task, because change is the Earth’s standard operating procedure. Rains fall, winds blow, sunlight and temperature sustains or kills plants. Nature has a way of rearranging the landscape. The most humans can do is slow that process down-just a little. But by studying how the land changes-geomorphology-humans can gain an edge in the game.

On North Carolina’s New River, boulders were placed at the base of the bank, and stacked higher at the bend, to stand up to the force of moving water.

“Along with being the company’s CEO, I’m also its senior geomorphologist,” says Wendy Goldsmith, of Salem, MA’s Bioengineering Group. “The scale of what I’m doing is sustainable design-on rivers and also on small-scale projects, such as urban development damage. We make sure every project defines ecological attention; we have to understand hydrology and what can be done to repair functions there.

“Our group has been working on projects that feature green solutions for 21 years,” she continues. “The first day you put concrete on the site, it gets wear and tear. The first day you put green solutions in, if you design it right, it can sustain and repair itself and will grow stronger over time. Self-regenerative and adaptive solutions are multipurpose; they not only hold onto the bank, but also help the ecology of the water, and its cleanliness.”

Goldsmith points out problems with concrete. “Making concrete puts CO2 into the air, and as it retains solar heat, concrete makes heat islands. Concrete solutions are just not working; they can lead to disaster. We have worked from coast to coast with some astonishing concrete repeat failures.” Bioengineering Group’s green successes make clients believers: “Some clients use us on a repeating basis, when they find out how easy and beneficial green solutions can be.”

One such project took place on Cincinnati, OH’s Mill Creek, a natural waterway that’s been abused over the decades, as it unfortunately runs through the city’s industrial and rail district. Portions of the creek have been routed through a cement culvert, but farther upstream the creek remained in a natural state. One such section abutted the capped Center Hill landfill. Water erosion in that area caused the creek banks to seriously erode, allowing landfill leachate to enter the creek.

“Mill Creek is filled with runoff, illegal dumping, and events from vandalism. A meteorological station there also housed a pumping station to capture the landfill’s leachate. Vandals would cause the pump to get broken, and the leachate would get back into the water,” Goldsmith explains. “Project design started in 1997. The first phase was “˜emergency’ work, because landfill leachate was leaking into the creek. The initial phase, which had been estimated as less than a mile, turned out to be 3 miles, all told. Later, other sections were reinforced-areas with less urgent needs, but which still required attention.”

Because the Mill Creek experiences high flows during certain times of year (snow melts, spring rains), the base was reinforced with stone. “We needed to put rock at the bottom of the creek slope. No form of vegetation will permanently withstand Mill Creek’s deep, high-energy flows if water’s there all the time. We used the rocks already there onsite, but changed their positions to make them work better at channeling the water, and to cover the clay hardpan. Actually, rains often allow good-growing-texture soil to wash down between the rocks.”

At the time, the city’s project manager was Jack Wachter, a senior environmental/safety specialist and certified professional geologist with Cincinnati’s Office of Environmental Management. “Soil bioengineering has been around for about 100 years. Although it continued to be used in Europe, North America seemed to forget about it,” he says. “We were glad to find Goldsmith’s firm was performing more natural solutions. Only about two or three companies in the US really understand soil engineering-Bioengineering Group is one of them-and their projects will last. The erosion control issue was solved, although methane issues from the landfill still need watching.”

After the rock footer was installed, live-cut branches (willows, cottonwoods, alders, dogwoods), or brush layers, were interspersed on the eroded slope between layers of soil; the branches were also wrapped in natural or geosynthetic material. When the branches were placed in an overlapping pattern, their tips protruded beyond the face of the fill. This positioning helps slow runoff velocity, and it also filters sediment from the slope runoff. (For slowing water velocity, a similar tactic is used in Japanese “rain chains.” Instead of gutters, decorative chains are hung from a house’s roofline. Rather than rushing over the side, water meanders down the length of the chain, slowing its speed and dispersing or lessening its eventual soil impact.)

The live cuttings soon developed root systems, which stabilized the slope against shallow sliding or mass wasting. As they grew, the plants added structural strength to the bank while also providing the site with natural, pleasing aesthetics. As area environmental groups had expressed interest in, and worked toward, making the Mill Creek a nature site, the natural bank restoration was greatly welcomed.

“About two years ago, we did additional work there, adding walking trails and a terrace near the bank so people could use and enjoy the site,” Goldsmith adds.

The natural solution also offered cost savings. Completed during the second quarter of 1999, the Mill Creek installation cost totaled $320,000 (including site analysis and design, construction, construction oversight, and post monitoring). “Traditional” methods such as concrete, drilled pier, sheet pile, or gabion walls were estimated to have run from $450,000 to $600,000.

“More people are moving toward vegetative solutions; unfortunately, sometimes not very well,” Goldsmith says. “If people build things the way they wish it would work, and they fail, that sends the process back a bit. Very few of us have been trained in the engineering properties of roots and soils. When doing a project like the Mill Creek, success is not only in the materials initially used, but also, plants adapt to change, grow, and get stronger. We see a lot of “˜turnover plantings.’ What we might plant will allow other species to come in-species well-adapted to the site, plants that absorb whatever leachate might escape in future.”

“Two years after the project was completed, Cincinnati experienced a big rainstorm. The day after the storm, Mill Creek was the highest I’d ever seen it, in my career,” Wachter says. “I was afraid of a washout, but everything held perfectly. The live stakes that went into the rocks grew very well and held the installation together.

“Sometime later, I went down to the site and found 50 or 60 small trees growing in the rocks had been sliced off. I was quite angry. The landfill was closed by a locked gate-who did this damage? How was it done? I called around to several agencies, trying to enlist help in solving this mystery. The Ohio Department of Natural Resources came down to give it a look: “˜Oh, yeah, that was done by a family of beavers,’ they said.” Wachter laughs. “Well, that’s what you get when you put an area back into a more natural state-it attracts wildlife.”

Natural Solutions to Nature’s Destruction

September 2004 was a rough month for Watauga County, NC. Hurricanes Frances and Ivan both roared through the area, severely eroding the south fork of the New River near Boone, NC. Approximately 325 feet of channel banks were reduced to vertical slopes ranging in height from 10 to 20 feet, placing an asphalt walking path in bordering Brookshire Park in jeopardy. Further exacerbating the problem, funding delays didn’t allow any work on the site for several years.

“I did the initial site visit in January, 2007,” says J.P. Johns, P.E., group manager of Watershed and Infrastructure Management for Woolpert Inc. in Greenville, SC. “Grant funding came from North Carolina’s Clean Water Trust Fund, but things took a bit of time from the start of the planning and permitting phase to the actual start of construction and installation. However, things moved really quickly once we got started. The project bid deadline was March 10, 2008; construction began on April 15 and was finished on April 29, 2008. Blue Ridge Grading of Burnsville, NC, did the actual installation.”

This section of the New River provided quite a challenge. Given a Rosgen stream classification of “F,” the 325-foot section featured an entrenched meander, an incised channel, and a high width-to-depth ratio, subject to very high erosion during significant storm events. More storms of 2004’s variety would create massive damage to the river and its adjacent properties. To project “what could happen” and “what might prevent it,” hydrologic and hydraulic calculations were completed to determine the expected stream flow elevations for various (one-, two-, five-, 10-, 50-, and 100-year) 24-hour storm events.

“In a true natural setting, a floodplain would exist next to the river; that’s nature’s way of dealing with high water in the river, without causing erosion,” Johns says. “But, since the park was already there, with a walking trail and soccer fields at the top of the bank, there wasn’t enough available land in which to establish a floodplain. For the same reasons, we couldn’t lower the riverbank. We had to fix the riverbank without making it any larger.”

The first step: Clear out existing failing trees and other debris. Next, large boulders were placed at the base of the streambank to stabilize the slope and also to lessen the impact of rushing waters on the slope. “On the toe, we placed the most rock in the curve, where the bulk of erosion was taking place. We had easy access to boulders in this area of North Carolina; it wasn’t expensive to get them. On the coastline? That’d be a different matter.”

Merely holding the slope against the water wasn’t enough; Johns determined that channeling the water away from the bank would help a great deal. “A true, flat, single-arm rock vane was placed in the river. When water comes downstream and hits that vane, instead of hitting the bank, the water moves back to the center of the channel.”

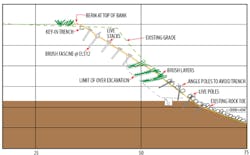

The channel banks were graded to a 1:1 slope, then stabilized using Profile Products’ GreenArmor System, consisting of Enkamat 7020 turf reinforcement mat (TRM) and Flexterra. The TRM was trenched at the bottom and top of the slope to a 6-inch depth and anchored using 12-inch staples. It was also installed in a “shingle pattern” (upstream matting overlapped downstream matting), to prevent its failure during high flow. The matting was then backfilled, compacted, and seeded with an appropriate grass mixture native to the mountainous Piedmont area. Because of the potential for high shear stresses, Terra-Shield, a prescriptive agronomic formulation, was added to the Flexterra for added ease of installation and long-term bank protection. The banks were then vegetated with live stake trees and shrubs.

“We used live stakes of black willow or silky dogwood trees, which are known for their great root systems, and received about 70% success rate,” Johns explains. “Profile’s TRM has enough open space so you can stick a live stake through it; you don’t have to cut the mat as you do with other brands, which lowers the mats’ effectiveness. We installed a lot of trees-that’s the key. The river has a pretty woody bank again. The trees’ roots hold the bank in place.”

The opposite bank was also reinforced. “On the far side, we removed some of the deposited sediment, actually lowering it several feet, to create a bench within the channel banks, so, if needed, the high water could flow up there. Wattles or sediment tubes were put there for sediment control while vegetation was establishing itself. This side is agricultural use; the property owner worked with us, helping to make the project a success.”

Considering climate changes, what once constituted an “X-year” storm may no longer be accurate. “For 100-year storms, etc., the parameters are changing,” Johns says. “Due to weather changes and storms increasing in intensity, we’re doing new floodplain maps. Some residents are surprised-“˜I was never in a floodplain before,’ they’ll say. Well, it’s never been mapped before.”

The riverbank’s restoration attracted new “residents.”

“This section of the New River is classified a Class C water body, meaning “˜waters protected for uses such as secondary recreation, fishing, wildlife, fish consumption, aquatic life including propagation, survival, and maintenance of biological integrity, and agriculture. Secondary recreation includes wading, boating, and other uses involving human body contact with water where such activities take place in an infrequent, unorganized, or incidental manner.’ Well, after we installed the vane, one of the project’s engineers, who’s a trout fisherman, noticed the vane had created a scour pool on its downstream side. In a few days, brown trout were living in there; they like the habitat. We actually put up a kiosk in the park, a fun thing that explained the entire project including some information about brown trout, so people could understand the benefits of putting in the buffer. To further involve people with the project, 6- to 8-foot paths were made, so folks could have access to the river.”

Nature is wild; parks are maintained. “We later found out the park maintenance people were weed-whacking our plantings, because “˜people can’t see the river!’ We had to install fencing and signs to explain that the plants all had a purpose. Whenever you do a project like this, you need to explain it to the right people.”

Green Engineering by Design

To aid in projects such as the one on New River, Buffalo Grove, IL’s Profile Products LLC is developing an entire product line, and philosophy, around “Green Design Engineering.”

“What we’re trying to communicate: Your palette starts with three components,” says Marc S. Theisen, M.S., CPESC, CPSWQ, CESSWI, a vice president with Profile. “One: Establishing vegetation achieves erosion control. Two: Select products that will give a balance, or harmony, in this triangle. Three: Controlling a project for the short term-for example, a flat residential yard that’s being seeded-requires less emphasis on erosion control and more on growth establishment. The site will drive the tasks required. Take a mine site, with lots of erosion and slopes; both erosion control and growth are challenging and important. Any product you use may need to last two or three seasons for the product to biodegrade, and it might take that long for the vegetation to take hold.

“A large facet of our Green Design Engineering: Fix the soil, select the right plant materials, then pick the right erosion control product to work with them,” he continues. “For best results, the first thing to do is a soil test, in which you’d look at variety of parameters. An agronomic soil test might be better than a geotechnical test, as you’re trying to ascertain “˜what’s the potential of this soil to sustain life?’

“Second only to water, soil pH is important. The farther you get from neutral, the fewer nutrients can get to the plants, and there’s also the chance of nutrients running off into receiving water bodies. At mining sites, pH can be as low as 3.0, sometimes caused by chemicals used in processing the mineral or ore, or by rocks that can give off acidity. Using lime to raise the pH in acid soils, or acidifiers to lower the pH in alkaline soils, gives whatever you plant a better chance of survival. Does the soil also need nutrients? Make sure what you use stays where you incorporate it. Slow-release phosphorus from organic fertilizer helps to offset rapid release of phosphorus, reducing the potential for it entering water bodies.”

Soil is not merely nutrients and dirt. “Some sites are just ground up rock. Look at the soil’s percentage of organic matter. If it’s less than 2%, you have to add some organic material, to feed existing, or supplemented, microbial sources.”

Profile’s interest in green design stemmed from clients complaining about less-than-optimal results. “We’d hear customers say, “˜There’s no erosion on our project, but nothing’s growing.’ We’d ask if they’d done a soil test, and a reply might be, “˜Um, it’s 3.7.’ So we decided to create a proactive solution.”

The company created Profile Soil Solutions Software (PS3), the industry’s first and only Web-based design and selection tool, which integrates erosion control engineering with agronomic components. “The software shows what one can do on their own site. People can download this software, send us a soil sample, and we’ll test the soil, sending back a report that provides the analytical data and offers soil amendments and fertilizer rates to correct deficiencies, excesses, or potential toxic conditions. To change soils, to increase organic material, could be cost prohibitive; changing the chemistry of the soil, creating a substrate to get things started, are steps in the right direction. For example, one might add mycorrhizae and biostimulants.”

As gardeners and farmers can attest, creating a great growing environment takes much work and time. However, most erosion control professionals don’t have the luxury of time.

“In a perfect world, we would go back and reapply products to sites that don’t respond quickly, but most projects are “˜one and done,'” Theisen explains. “Many erosion control contracts have performance requirements; however, maybe a year later the site doesn’t look so good again. By helping them boost their soils, we’re helping our clients.”

Profile plans more for the software. “The next thing we’re getting ready to implement is a seed selection module. Should you use natives, turf grass, cold- or warm-season species? This part of the computer module would help customers make a self-assessment, then we’d try to decide who we can consult with to help them. Since we service clients all over the world, with a vast variety of soils and climate conditions, this part of the software is still in work. Also, since we don’t supply seed, we need to learn what’s out there and who sells it.”

Once the initial data are plugged in, customers can input their site’s situation. “The software will tell them what can be used; maybe five of our products will show up as suggestions. We help them pick something that works for their site, while also keeping an eye on costs.

“There are a lot of things out there we can’t control,” he goes on. “Maybe someone graded the site wrong. We try to be by customers’ sides with projects, ensuring that our products are mixed and installed correctly, but we can’t always be there, although we make the effort to be supportive. For example, a client might have an issue with maintenance: “˜We stopped by the site after a big rain, it doesn’t look good-now what can we do?’ Profile Products can help, with suggestions on how to solve problems that might pop up, using products that are environmentally safe, offer low toxicity, and recycled paper, and so on. On that account, Profile has recycled over two billion pounds of paper and wood through the years.

“We use natural sources for almost everything we make,” he concludes. “Profile also uses netted products that are less apt to entangle wildlife. A big step in the “˜greening of America’ is capturing stormwater and not letting it run off. When you think of it, erosion control is actually stormwater management, because it’s keeping soil in place, where it needs to be.”

Reference

Barrett, K., W. Goldsmith, and M. Silva. 2006. “Integrated Bioengineering and Geotechnical Treatments for Streambank Restoration and Stabilization Along a Landfill.” Journal of Soil and Water Conservation 61(3).