Many things are dictating the choices of temporary sediment control these days: stormwater pollution prevention plan (SWPPP) compliance and other environmental concerns, product strength, ease of installation, productivity concerns, minimal maintenance, reduced labor costs, and other budgetary factors.

While temporary sediment control may consist of a BMP used on a short-term basis, the choice of what to use will have long-term implications based on its success.

Through his company, 6K SWPPP, in Mesa, AZ, Carl Bloomfield provides inspections and writes SWPPPs for homebuilders and developers in the Phoenix and Tucson metropolitan areas.

Bloomfield uses Gator Guard on short-duration projects, such as the construction of the Chicago Cubs’ new spring training facility in Mesa, AZ. The facility is being built by Hunt Construction. In addition to the training facility, the site will feature a park and artificial lake stocked with fish; water for the lake will come from the Salt River Project canal system. The park and the lake are connected by a tree-lined walkway.

“This site has always been a golf course,” says Bloomfield. “It’s also been a regional retention drainage facility. Everything drains to it because the golf course could handle it. It needed to continue to be that way but as is often the case, construction stockpiles going up adjacent to the road needed some temporary sediment control.”

Bloomfield’s company installed 2,000 linear feet of Gator Guard to help protect against sediment washing onto the road onsite as a temporary measure for four months while the construction company was grading that area. Gator Guard is a reusable sediment control wattle manufactured from recycled foam and UV-resistant geotextile and is designed to provide 20 times less soil loss than straw wattles. The 8-pound wattles measure 6 inches by 25 feet. An apron minimizes underflow washouts.

The choice of sediment control measures was particularly significant for those times of the year when the region is affected by “monsoon storms,” says Bloomfield.

“They can be quite violent and drop a lot of localized rain, and this site seems to be a hot spot for that,” he says, adding that the city of Mesa was intent on requiring strict temporary sediment control measures. “They just wanted silt fence all the way,” Bloomfield says. “Silt fence is difficult to install and more costly, so I suggested Gator Guard.”

behind the EnFencer, into which a crimping disk presses the material.

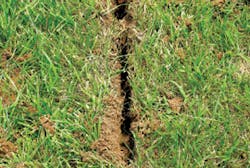

The topography is another reason Bloomfield used Gator Guard. “It’s very cobbly, and I didn’t want to have to install regular stakes and have straw wattles,” he says. “Having stakes in rocky soil is difficult at best and painful at worst. It makes sense to install Gator Guard, which requires you only pound a nail instead of a whole stake down into the ground.”

Bloomfield says he chose Gator Guard for its effectiveness in a temporary situation.

“When you’re throwing down straw wattle and putting down stakes through it, when you go to take it out, it falls apart,” he says. “It doesn’t get reused. With Gator Guard, you can pull it all back up, throw it on a trailer, haul it to another job site, and use it again. I use Gator Guard whenever I can just because of its ease of use.”

No maintenance is required with the use of Gator Guard, Bloomfield says. “It stays strong and true the whole time. But at the same time, I didn’t know if they were going to pull the temporary fence down” for access to parts of the site. “You’re able to pull Gator Guard back and you can tack it back down. It’s easily moved that way, whereas straw wattle just doesn’t do it.”

However, in conjunction with Gator Guard, Bloomfield also chose to use silt fence and a typical wattle as a long-term solution for the entire construction project, slated to last up to two years.

Soil Types in California

Harness Consulting in Folsom, CA, provides a wide variety of services, including erosion and sediment control, inspection, and SWPPP implementation.

Jerry Harness, a partner in the company, considers several factors when choosing temporary sediment control techniques. “I look at the soil types and for any water bodies that could be related to the waters of the United States,” he says. “That could impact the job, as well as any recommendations that the engineering contractor would have for their SWPPP.”

He also reviews recommendations made for particular BMPs, and if he sees a potential problem, he will get in touch with the engineers and client to figure out what would work better to accomplish the goals of the SWPPP.

Harness often uses Heavyweight wattle and gravel bags from World Textile and Bag. The Heavyweight Wattle is a full rebound sediment control barrier designed to handle new home development site challenges; it can be installed on soil, concrete, or asphalt. It is listed by Caltrans as a flexible sediment barrier. The wattles link together to form a continuous barrier. They require little maintenance and are reusable.

The wattle features dewatering and silt filtration properties, filtering 96.6% of sediment, and is ASTM D7351 field tested. “I use the“One is an emergency protection device for preventing anything from spilling into a drain inlet-any chemical spills or what have you,” says Harness.

Harness works in a variety of weather conditions in California from Redding to Fresno that call for different temporary sediment control measures.

“We have so many different soil types and weather types,” he says. “In the northern part of the state, we have a lot of rain. In southern California, the state is a little drier in the wintertime, as well as in parts of the Bay Area. In an area that’s going to have 35 inches of rain in a season, we’re going to have a lot more BMPs in place than in a drier climate that gets 10 to 14 inches of rain.”

The same holds true of soil types. “In the north of the state, there is a lot of diatomaceous clay. Sometimes you have to end up doing an advanced treatment process there,” Harness says. “Sometimes you’re able to have containment, such as a sediment basin, onsite to help you out a lot.”

The size of a project also determines approaches, Harness adds. He uses a combination of BMPs as needed.

“I use a lot of straw blankets and geofabrics; I use everything from matting to the Heavyweight product,” he says.

In many new residential developments, the appearance of the site, including BMPs that are in place, can help boost sale appeal. “Developers want a nice, clean-looking job site,” says Harness.

He says his clients are usually quite specific as to what types of BMPs they want. He began using products from World Textile and Bag when working with a housing developer whose project manager was seeking an alternative to straw wattles, which had to be replaced on a frequent basis. The developer also sought a product that withstands equipment running over it without it getting destroyed. The key to the success of the Heavyweight products is proper installation, says Harness.

“I’ve gone on some sites where it isn’t properly installed,” he says. “They don’t get the life out of it. Maintenance also is key-going by and picking up any debris and trash that blows in behind it to keep it clean.”

Harness finds that the Heavyweight products also save money on a job site. “Instead of constantly sending an implementation company back out to repair stuff constantly, you’re able to put the product in the ground, do basic maintenance to it, and when the job’s done, you pull it out of the ground and you take it to the next job.”

In some instances, grading the site in stages is another approach to sediment and erosion control. Harness subcontracts work to grading contractors, working closely with them.

“We’re in there usually after they finish grading slopes and the lot pads as well as any other roads and sidewalks. We come in right behind them,” he says.

“You’re not able to do the mass grades like you used to in California,” he notes. “With the underground portion of it, you have to button it up every day, so they’re not open and exposed as much to the elements like they would in the past, where crews would just open up a whole job site and put out some perimeter control, and that was it. Now when they finish a phase, the wattles are down and the seed trucks are right behind.”

Harness also performs maintenance of drainage inlet protection, repairing any wattle that’s been damaged from wear and tear, weather, or neglect. He performs site inspections, maintaining SWPPP logs and keeping clients in compliance with the state of California through testing and monitoring of any sampling points.

Providing Pre-Made Products

Sometimes it’s not just what’s being used for temporary sediment control on a job site, but how it’s being used. Case in point: bringing products in on pallets.

That’s the current approach of Soil-Tek, whose president, Tom Truelsen, notices that practice is trending, as well as the general use of filter socks for sediment control, especially in Pennsylvania around natural-gas operations.

“People are realizing it’s easy, quick, and effective to install,” he says.

While that’s a benefit on job sites, it’s particularly important when working for a client whose request may come at a moment’s notice. Such is the case with Hubbell Homes, an Iowa homebuilder that constructs about 150 to 200 homes in a development a year and needs temporary sediment control, notes Truelsen, whose company provides the products and services for the homebuilder.

“When they’re just about to start construction on a new group of homes-and it might be 13 homes at once-they’ll call us out to wrap the lots with filter sock,” Truelsen says.

Soil-Tek makes its own filter sock fabric, e-tube brand filter sock, a biodegradable product filled with compost and mulch that filters water and traps sediment.

“We used to send blower trucks out that would fill the fabric with the wood mulch to make the filter sock and send a truck out to wrap the lots, but we’ve gone to a new system that allows us to pre-make the filter sock at our facility,” says Truelsen. “We pre-make it on pallets, shrink wrap it, and deliver it out to the site on a flatbed truck, and our employees will install it.”

That approach is just a fraction of the cost and time it takes to use a blower truck at the job site, he adds.

When Hubbell is ready to start construction, its engineers will stake out the lots, and Soil-Tek arrives at the site to wrap the lots with the e-tube, notes Brent Cambridge, project manager.

“This all has to be done before any construction can start to meet city requirements,” he says. “We’re really the first phase of the homebuilding.”

Timeliness is of the essence, Truelsen points out, adding that his company may be called upon to provide sediment control at a moment’s notice. “Often we’ll get a call from Hubbell in an afternoon, and they want the work done first thing in the morning,” he says. “So we have these filter socks already made, palletized, and waiting in shrink wrap in our facility. We make them during our downtime and off hours, and they’re ready to go.”

The approach also is beneficial due to tight spaces in residential development construction, Truelsen says.

“The big challenge is being able to maneuver onsite in tight spaces between homes in a residential environment and put this material down,” he points out. “When we had big blower trucks, that was often difficult because they are so large. This is really good for an urban setting.”

Soil-Tek uses the e-tubes in combination with other measures. “We may hydromulch and hydroseed some of the area in addition to the filter sock,” says Truelsen. “Sometimes, we’ll use silt fence in an urban environment around new construction of homes. But they really don’t like to put in a steel post, because they’re worried about safety, and even aesthetically, the filter sock looks a lot better.”

The company also uses mulch for a temporary driveway to reduce the sediment track onto the street, “so you don’t have a big mess from the subcontractors,” says Cambridge.

Additionally, Soil-Tek places inlet protection. “Any mud that might leave the site is captured, and we’ll clean those out later,” says Truelsen.

Before sod is installed, the e-tube is cut with a utility knife and the mulch is spread onto the ground and graded into the yard, creating a soil additive, Cambridge says. “What’s left of the erosion tube material just goes into the Dumpster,” he adds.

Another benefit of filter sock technology is that it doesn’t have to be trenched in, Truelsen says. “It’s a fairly heavy product that can be put down in all four seasons. In Iowa’s snowy winter conditions where you have other products that you have to trench in such as silt fence, you can’t put the product down, but this you can do year-round. In the spring and the fall when it’s muddy, we get a lot more filter sock installations.”

Iowa’s soils are loamy and fertile, conducive to farming. “In these type of soil conditions, when you do get rain events, you’ve got a lot of soil that can move,” Truelsen points out. “The good thing about the filter sock technology is it doesn’t pond like silt fence. It will hold back the sediment and slowly release the water through the sock.”

Soil-Tek does a great deal of work with homebuilders, developers, and the Iowa Department of Transportation, providing erosion control seeding and planting trees and shrubs along interstate highways. The company also is selling the palletized product to other erosion control supply companies, as well as homebuilders, developers, and county governments seeking to do the installation themselves, Truelsen says.

The EnFencer

From job-site challenges come new products and approaches. Such was the case years ago for Jesse Putman, project manager with Putman Erosion Control in Ashville, AL. The company does a variety of erosion control and site work with silt fence, hydroseeding, reclamation, and water filtration.

Putman got a patent on a wire-reinforced silt fencing system he invented, the EnFencer, for his private use. The machine enables installation of wire and fabric in one step.

“The first job we ever did in 2001 was the reason we invented it,” he says. “We had a job with 25 miles of silt fence to do. We were using a conventional method, and we just weren’t making any progress. I came up with that design, and we built it and got a patent on it and have been rolling with it ever since.”

With the EnFencer, Putman and his crews were able to go through the muddy, swampy areas in places where the trenchers wouldn’t go. “We could go through there with the tractors, pull that machine, and put silt fence in the mud,” Putman says. “It worked on slopes and hills. We put it on big tractors to go in rougher terrain areas. The biggest thing is getting into places that you can’t get in to with a trencher.”

The EnFencer can be placed either behind a farm tractor or in front of a skid-loader; some contractors mount it on the back of small dozers, says Putman. The machine mounts to any category 2, three-point hitch and minimum 45-horsepower tractor. It requires no more than two people to operate.

After locating and marking utilities, the contractor installs material shafts for the wire and fabric, securing them in place by key. Any type or width of geotextile fabric or wire fencing can be used; the machine also can be used to install rolled erosion control products.

The roll core centering spools are installed on the fabric shaft. The geotextile fabric roll is installed on the shaft closest to the tractor and wire roll on rear shaft.

“You put a roll of wire around one of the spool rods and a roll of geotextile fabric on another rod, and you pull the fabric off the spool,” says Putman. “It goes around a crimping disk on the back of the machine, and it’s got a coulter wheel that cuts through the roots of the grass and small brush for a clean cut.

“Then you’ve got a shank-type ripper behind that rips a narrow slot in the ground. Following that is a crimping disk and a big wheel that pulls the wire mesh and the geotextile fabric off the spools, pulls them back down, and crimps that material down in the ground, pulling it tight. You can adjust the depth to how you want it and then the dirt falls in place behind it.”

The machine uses a hydraulic locking device when installing fence into the ground. The EnFencer’s method is designed to prevent blowout and create minimal soil disturbance.

Putman Erosion Control has installed up to 7,000 feet per day with the machine. Not counting the time putting in posts and clipping it up, a contractor can put in more than 100 feet per minute with the machine, Putman says.

Productivity is its main benefit, Putman says. “We can make so much more production with that than we do with a trenching-type method,” he says.

A job in Montgomery a few years ago, the Montgomery Outer Loop, involved a road extension project to alleviate traffic. “That job went through some swampy area where a four-wheel-drive tractor couldn’t even go through,” notes Putman.

“It was wet and muddy. We moved a big dozer to the front of the tractor to go through the mud. The dozer would pull the tractor through the wet muddy areas and the EnFencer would be right behind it, installing the silt fence.”

Putman Erosion Control has also used the EnFencer on right-of-way jobs for transmission lines through mountains. “We’ll pull a dozer and the EnFencer up hills and down hills,” Putman says. “An average machine couldn’t do all of that work.”

Any topography upon which a contractor can run a machine will accommodate the EnFencer, he adds. While the EnFencer works best in cleaner soils, it can do the job in rockier soil to a certain extent, says Putman.

“If it’s just pure rock, nothing is going to work,” he adds. “It actually works better in rockier-type soils than the others, like a trencher, might because it doesn’t have to trench a hole in the ground and fill it back up. It actually slices. “We can hit a big rock and pull up a little bit, jump over the top, and dive right back down on the other side of it, so we can fill the ground out a little better.”

Just as Putman Erosion Control is the first one on a job site, the company also is the last to leave. “We do all of the hydroseeding and vegetation work, and once we get everything vegetated, we’ve got a machine that comes back in, pulls it up out of the ground, and rolls the silt fence back up so we can recycle it,” says Putman.

The EnFencer hit the general market in 2005 when other contractors expressed an interest in using it.

Putman Erosion Control sold 50% of the patent royalties of EnFencer to Gary Norwood of Sunshine Supplies in Birmingham, AL. Local manufacturers build the machines to order, which are sold through a company called Erosion Control Implements.