About the author: Myles Gray is faculty research assistant for Oregon State University. Gray can be reached at [email protected] or 541.250.2250.

A recently installed storm water treatment project in Port Townsend, Wash., uses locally sourced biochar, a carbon-negative byproduct of biomass energy production, as filtration media to remove heavy metals from storm water runoff at the Port of Port Townsend (PoPT) Boat Haven facility. The project was a collaborative effort to design and optimize filtration devices using biochar sourced from the neighboring Port Townsend Paper Corp. (PT Paper). A successful pilot project installed in April 2014 was followed up with a larger installation in November 2014 that will help the site meet storm water discharge benchmarks for copper and zinc set by the Washington State Department of Ecology.

Port of Port Townsend

Port Townsend sits at the northeast tip of Washington’s Olympic Peninsula and is surrounded by natural beauty: the clean waters of the Puget Sound, the jagged peaks of the Olympic Mountains to the southwest and the distant snow-capped volcanoes of the Cascade Range to the east. Locals are quick to point out that the town sits in the rain shadow of the Olympic Mountains and receives only half the rainfall of Seattle to the east. The rain that does fall, however, creates water quality problems at the PoPT, transporting zinc and copper into the waters of Puget Sound via runoff.

The PoPT maintains one of the last fully operational boatyards in the Puget Sound region, providing boat maintenance space for ships from as far away as Alaska’s Aleutian Islands. Boat maintenance and the presence of galvanized roofs contribute to copper and zinc in storm water runoff. The level of these contaminants has exceeded the site’s storm water discharge benchmarks, prompting corrective actions that are now underway at the site.

What Is Biochar?

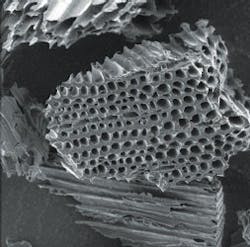

Biochar is a carbon-negative byproduct of renewable biomass energy production that can be derived from nearly any biomass. It is similar in appearance to charcoal used for grilling, but is used for environmental applications. The material is highly resistant to decay, lasting for up to 1,000 years in the environment, thereby sequestering carbon from the atmosphere. Biochar’s physical and chemical properties make it suitable for environmental applications; in many ways it can be thought of as a lower-cost version of activated carbon.

The key to biochar resides in its enormous surface area; a single gram of material can contain more than 4,000 sq ft of surface area—equivalent to a standard residential lot. The surfaces have unique chemical properties that enable the material to remove dissolved heavy metals and other contaminants from water, at a fraction of the cost of technologies like activated carbon and ion exchange resins.

Optimizing Biochar

The PoPT embarked on a collaborative effort to explore biochar as a sustainable alternative storm water filtration media. Softwood biochar for the project was sourced from boilers operating at the neighboring PT Paper. Historically, this material has been considered a waste product.

After a series of planning conversations, the project began with a research and development (R&D) program conceived and conducted by researchers at Oregon State University and BioLogical Carbon LLC, a pioneer in the field of biochar technology. The R&D phase received critical funding from the Pacific Northwest Pollution Prevention Resource Council and focused on two goals: Optimize high-flow-rate, biochar-based filtration media for removal of copper and zinc from storm water, and design filtration devices that utilize the optimized filtration media.

The R&D effort resulted in the development of a custom biochar-based filtration media blend capable of removing more than 99% of copper and zinc from influent storm water under laboratory settings, as well as the design and construction of a patent-pending up-flow filter.

Pilot Project & Full Installation

A pilot project was installed at the PoPT in April 2014 to test the performance of the biochar filtration blend within the up-flow filter. The pilot monitored treatment of roof runoff that was extremely high in zinc content for approximately six weeks. During that time, the up-flow filter achieved removal rates of more than 94%, 67% and 99% of copper, lead and zinc, respectively.

Based on pilot project results, more biochar-based filtration was incorporated into corrective action plans at the PoPT to reduce copper and zinc in storm water runoff, including installation of biochar up-flow filters at 18 roof downspouts known to have high zinc loads, as well as two custom-built in-ground vessels using the biochar-based media to treat surface runoff laden with copper.

JoFran Enterprises, a local Port Townsend small business, coordinated and oversaw completion of the project. The Washington State Department of Commerce provided $50,000 in grants to help finance the project. Installation began in November 2014, with monitoring of all devices underway and results available in the spring of 2015.

Innovative Approach

This approach to storm water treatment may well provide an example of effective filtration media and system design that not only achieves benchmark compliance, but also makes use of an organic waste product, employs local businesses and sequesters carbon—at a fraction of the cost of traditional alternatives.

Download: Here